R&D QMS Process Training

The purpose of the R&D process training guide is to secure the competence of R&D processes through a structured way of defining training needs, planning training execution, and maintaining training records.

Training principles

- Training shall be driven based on organizational needs balanced with individual goals.

- The goal of training is to secure competence that can be executed through many ways like self-studies, e-learning, classroom training, and mentorship.

- The Cluster Leads in each local line organization are responsible for ensuring the staff members are trained.

- Cluster Leads are responsible for maintaining a training log for their employees and consultants.

- Everyone in R&D needs to complete the PCP R&D Processes Basic Training and renew it every 5th year.

Training set up

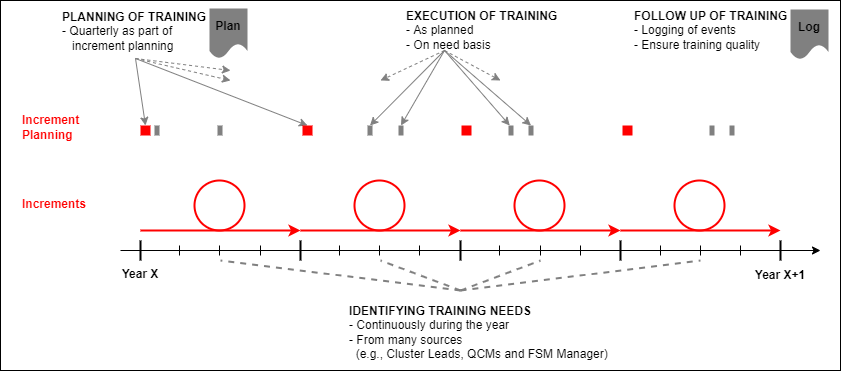

Training is planned in a quarterly cycle synchronized with the development increments. The Cluster Leads in the line organization are responsible for coordinating all training.

The key artifacts for coordinating the training are the training plan, which outlines the different training sessions to be performed in the next increment, and the training log, which maintains all performed training mapped to individuals.

The Project Description and Plan, and the Configuration Management Plan can also identify training needs.

An overview of the training activities is described below:

Training activities

Identifying training needs

Input on training needs is collected continuously and summarized quarterly. The main sources are:

- Cluster Leads are responsible for identifying training needs on all levels. This could e.g. be based on individual PDAs, process improvement initiatives, or long-term strategies.

- Release owners shall identify and communicate the needs for any training for the project as part of the quarterly increment planning.

- Development teams shall identify and communicate the needs for any training for the members as part of the sprint/increment retrospectives and quarterly increment planning.

- New resources in the development organization

- All process changes implemented are communicated each quarter. Some of these process changes may imply a need for training depending on the changes and the recipients.

- Based on assessments of ongoing development projects, QCM shall communicate any identified needs for training.

Planning of training

The Cluster Leads in the line organization are responsible for collecting all training needs and quarterly establishing a training plan. The plan can result in individual, stream, team, or line-organized sessions.

The safety training is planned and organized by the safety team.

Execution of training

Training shall be executed as planned. If urgent needs are identified during an increment it shall be communicated to the line organization that evaluates if it can be performed during the ongoing increment.

Follow-up and logging of training

The local line organization maintains the training log, managed in long-term storage, and shall be used to document performed training. It should indicate which individual has received what training and when. Competence achievements through self-studies and mentoring shall also be documented. The format is up to each local line organization.

An example of mentoring follow-up: 7PAA008836 "Mentor-Mentee training log".

Qualitative follow-up of training (internal as external) is encouraged – but doesn’t need to be documented.

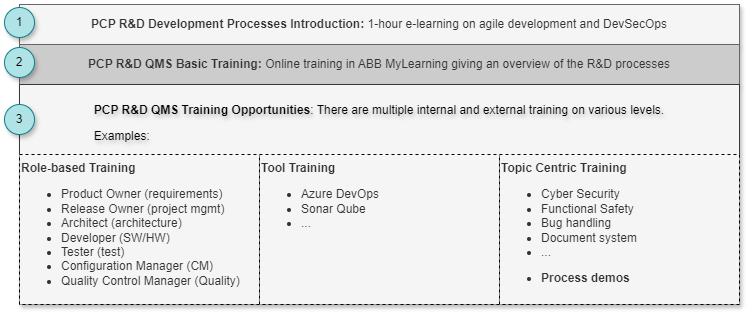

Type of training

There exists a variety of different training, from introductory to specialized:

A list of existing training is maintained on SharePoint

Training artifacts

As part of managing and delivering training, these are the involved artifacts:

| Artifact | Purpose |

|---|---|

| Training plan | The plan contains the training events |

| Training log | The log shows all performed training per date and individual |

| Process training material | For each process area, the process team maintains the training material |

Roles and responsibilities

The key roles involved in managing training:

| Role | Responsibility |

|---|---|

| Cluster Leads | The Cluster leads in the line organization are responsible for collecting the training needs, establishing the training plan, and following up on performed training. |

| QMS R&D Process Teams | The different process teams are responsible for maintaining training material, especially for basic process training. They are also delivering basic process training upon request from the line organization |

| Safety Team | The safety team is responsible for coordinating and delivering safety training (see chapter on safety training) |

PCP R&D Processes Basic Training

The PCP R&D Processes Basic Training is an online training covering the whole development lifecycle. It consists of an overall introduction to PCP R&D Processes and training modules for the different process areas:

- Master processes, SPI & IPM.

- Quality and KPIs.

- Requirements.

- Architecture.

- Software Development.

- Hardware Development.

- Test.

- Release.

- L4 and Maintenance.

- Cyber Security.

- Configuration Management.

The training is mandatory for all employees working on assignments governed by the PCP R&D Processes. It is also mandatory for all consultants working on “Safety” projects. For other consultants, the country hosting manager decides whether the training is mandatory or not.

Employees and consultants required to participate in the training should complete the training within the first 6 months at PCP R&D. Thereafter, they should renew the full training every 5 years to be updated on process changes, and to fulfill the standards.

Process training material management

The process training material is managed by the different process teams. Based on the needs identified by the line organization the process teams develop relevant training material.

For the basic process training, there exists a set of basic presentations. The process teams are responsible for the content of the presentations and shall approve any updates.

Functional Safety Competencies and Training

To fulfill requirements of IEC61508-1, all persons with responsibility in the management of functional safety products, within R&D, shall have the appropriate competence (i.e. training, technical knowledge, experience, and qualifications) to fulfill their roles.

The main purpose of the R&D, Functional Safety Training is to consistently provide the mandatory level of functional safety training by:

- providing a basic understanding of IEC 61508 Functional Safety framework and lifecycle

- introducing the ABB approach to fulfill Functional Safety requirements

- raising the awareness and attention of the employees to R&D Functional Safety processes

The competencies need to be documented. PCP R&D safety team is responsible for providing Functional Safety training for PCP R&D. The mandatory functional safety training package (classroom) will cover the following topics:

- Introduction to Functional Safety and IEC 61508

- Clarification on Safety Handbook and ABB Approach to IEC 61508 documents

The target audience of the Functional Safety training is:

- Resources to be involved in Functional Safety related activities are required to participate in the “Functional Safety Training for New Employees”

- Resources involved in Functional Safety related activities who have had Functional Safety training more than 5 years ago are required to undertake the “Functional Safety Refresh Training”

Notes

- Functional Safety related activities are performed in both safety and interference-free development activities.

- Cluster leads are responsible for requesting training from the PCP R&D Safety Team.

- E-learning providing an introduction to Functional Safety cannot be a replacement for classroom training. During exceptional circumstances, a person can attend e-learning and work in safety-related development under supervision until they attend regular training. This needs to be communicated and discussed with the PCP R&D Safety Team.

The duration for Functional Safety Training for New Employees is 7 hours in total (roughly 1 day). For Functional Safety Refresh Training the duration is 3.5 hours (roughly ½ day) with a reduced scope of the full training, mainly focusing on the Safety awareness and updates in the Safety related Process/Guidelines. The content of the Safety Training could be customized by the trainer according to the request and different project activities and products of each R&D site.