Explosion Protection

Explosion protection is the method called which reduces the risk of an unwanted ignition of an explosive atmosphere. The statutory definitions of explosion protection - derived from the health and safety at work regulations - are related to workplaces.

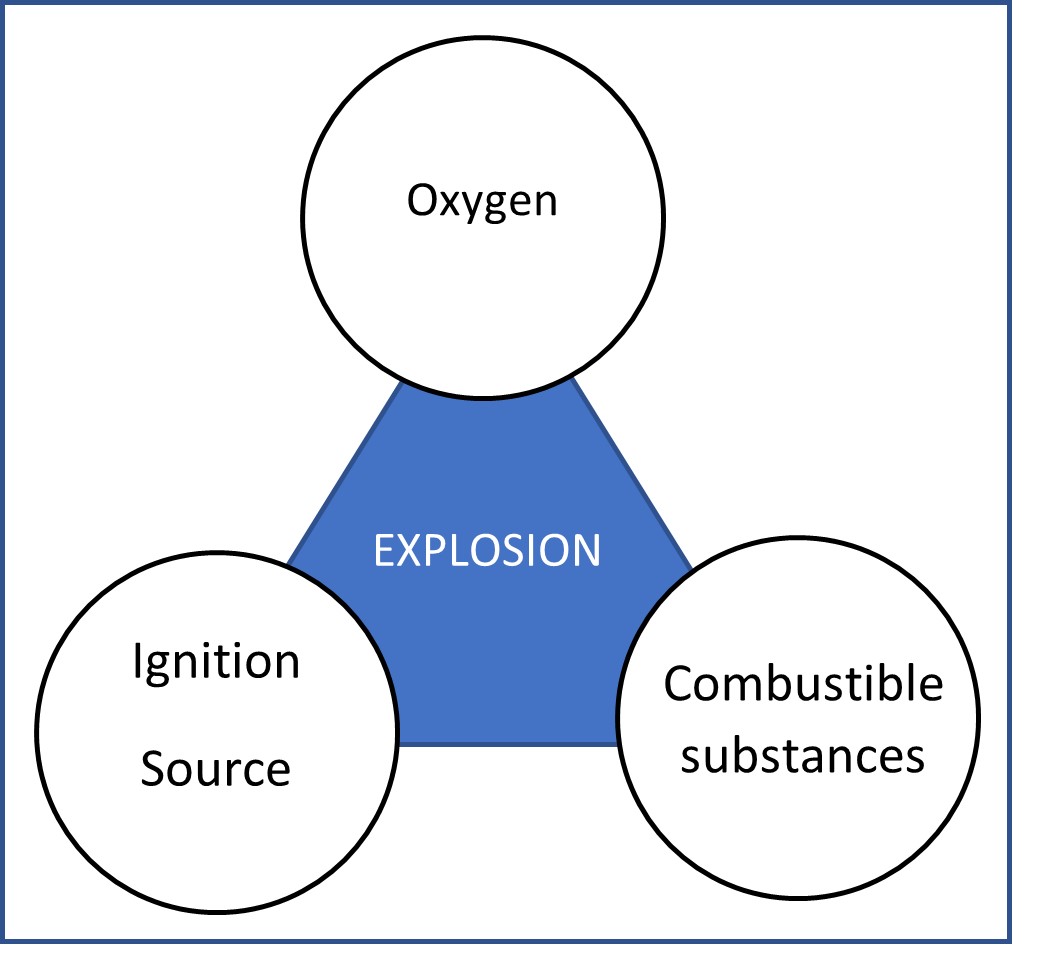

An explosion only can occur when three factors are present at the same time. Oxygen (air), combustible substance, and an ignition source. This is visible in the so-called combustion triangle.

Combustible substances are gases, vapors, mists or dust. The mixture of oxygen (air) with these substances is called an “explosive atmosphere”. In many industries such as oil and gas, chemicals, petrochemicals, pharmaceuticals, fertilizers and so on, combustible substances can escape in the course of manufacturing processing, transporting or storing. In these cases, an explosive atmosphere may arise. If an ignition source is also present at the same time, the probability of an explosion is very high.

With the use of technical equipment in such industries a large number of ignition sources are possible. Ignition sources are:

- Hot surfaces

- Flames and hot gases

- Mechanically generated sparks

- Electrical systems

- Electrical equalizing currents, cathodic corrosion protection

- Static electricity

- Lightning

- Electromagnetic waves (high frequency)

- Optical radiation

- Ultrasound

To reduce the risk of ignition or to reduce the impact of an explosion different ways of explosion protection or a combination of these levels are used. The different levels are:

- Primary explosion protection

Primary explosion protection aims at either substituting or reducing the quantity of the flammable substances or the atmospheric oxygen to a level where there is no danger of an explosive mixture forming. - Secondary explosion protection

Secondary explosion protection is required if, despite primary explosion protection measures, a hazardous, potentially explosive atmosphere can form. The ignition of this hazardous, potentially explosive atmosphere must be effectively prevented. - Tertiary explosion protection

If the primary and secondary explosion protection measures are not enough, additional protective measures shall be taken. The purpose of these is to limit the impact of an explosion and/or to reduce it to an occupational health and environmental safe level.

Ex Standard Basics

Zones

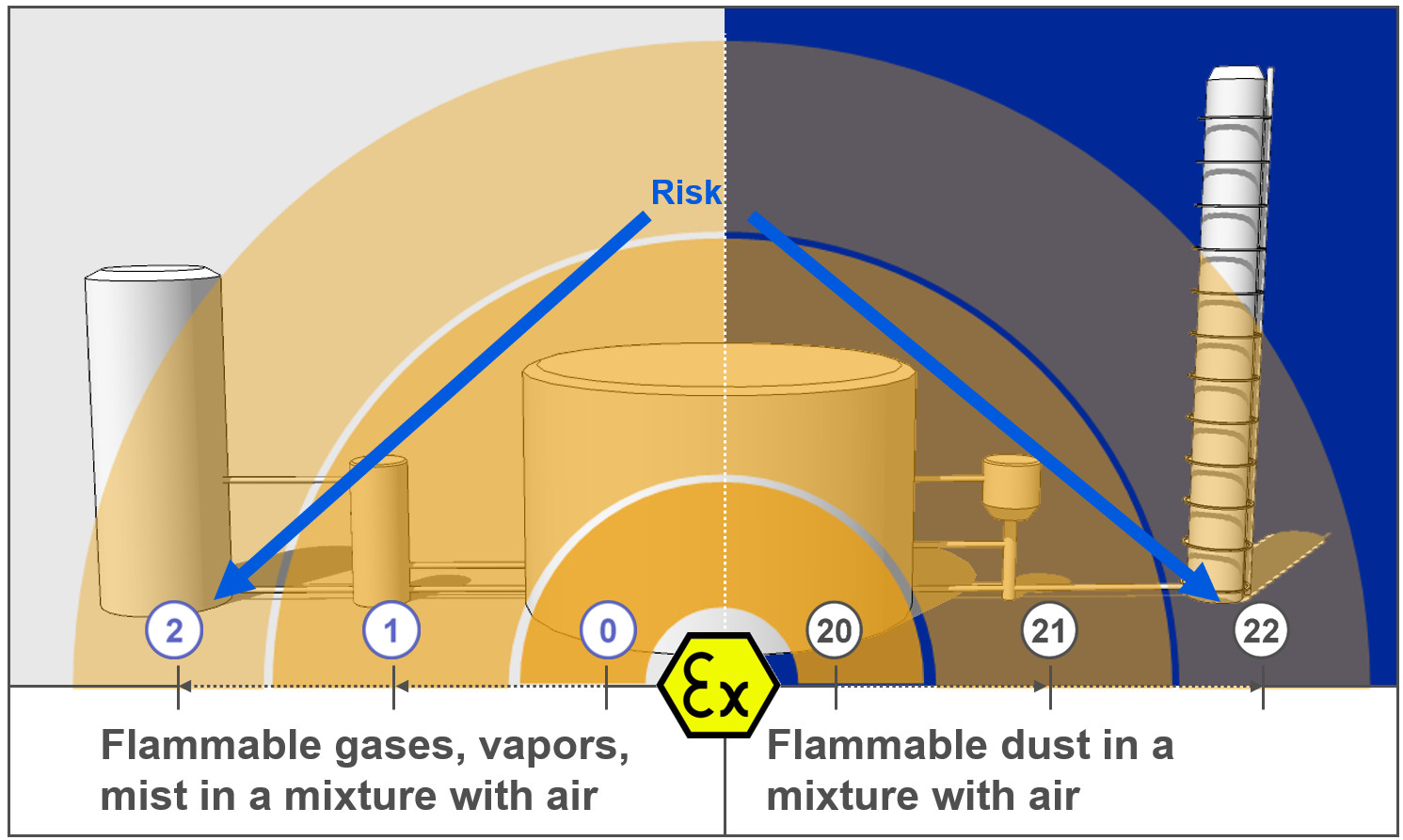

Hazardous areas are classified into zones for ATEX and IECEx. Zone classification reflects the likelihood of the occurrence of an explosive atmosphere.

- Zone 0/20 an area in which an explosive gas/dust atmosphere is present continuously or for long periods or frequently.

- Zone 1/21 an area in which an explosive gas/dust atmosphere is likely to occur periodically or occasionally in normal operation.

- Zone 2/22 an area in which an explosive gas/dust atmosphere is not likely to occur in normal operation but, if it does occur, it will exist for a short period only.

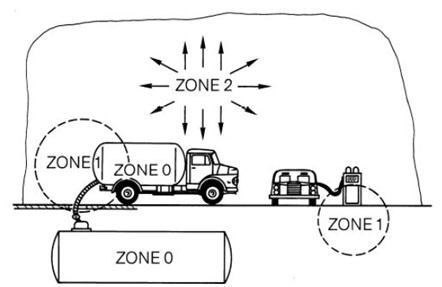

Examples of zones in a fuel station

- The fuel tanker and the tank of the gas station are classified as Zone 0 because there could always be an explosive atmosphere (Constant, long-term, persistent)

- The filling area surrounding the fuel tank and the area surrounding the fuel pump** are classified as Zone 1 because there could only be an explosive atmosphere when it is used. (Occasionally)

- The rest of the gas station is classified as Zone 2 because most of the time the mixture is too lean in this area to be ignitable (rarely).

Gas classification

Different gases, vapors, mist and dust require different levels of energy to ignite. To indicate this the combustible substances are grouped into different classes. The following list shows the maximum energy level that can be discharged without igniting the related gas air mixtures:

| Class | Maximum energy level |

|---|---|

| Group I (found below ground, in mines) | 200J |

| Group II (Gas) Group IIA Group IIB Group IIC | 200J 60J 20J |

| Group III (Dust) | 200J |

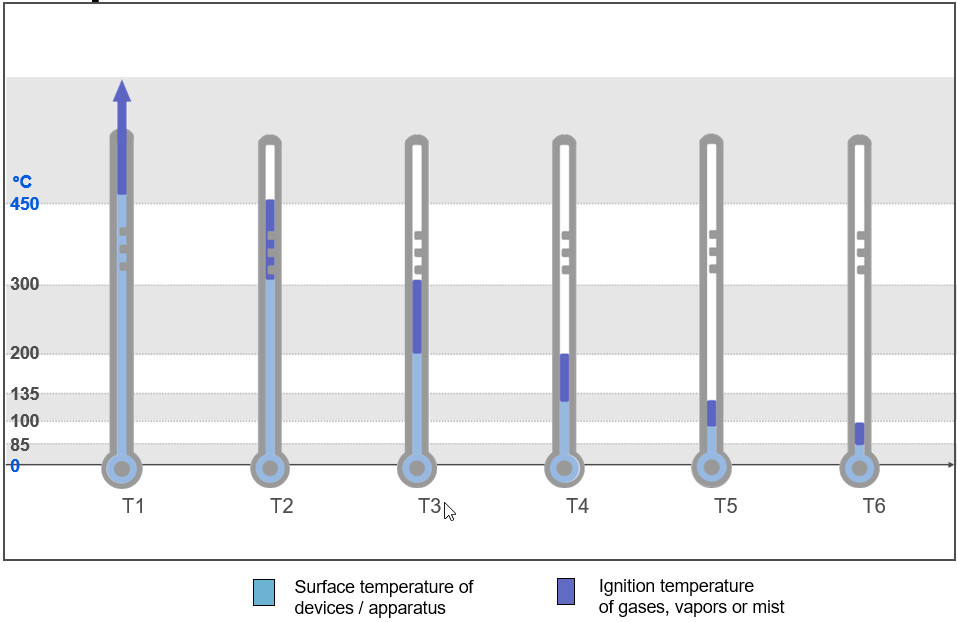

Temperature Classification

The ignition temperature of an explosive gas atmosphere or dust cloud is the lowest temperature of a heated surface at which a mixture of air and combustible substances in the form of gas, vapor or dust may ignite in the specified conditions.

Combustible gases and vapors are classified into temperature classes according to their flammability. The maximum surface temperature of electrical equipment must always be lower than the ignition temperature of the gas or vapor and air mixture in which it is used.

Ex Protection Methods

To reduce the risk of ignition, electrical equipment, which is used in an explosive atmosphere (Ex Zone) needs to support some protection methods. The methods are described in the EN or IEC 60079 standard series.

The following part shows some examples of Ex protection methods that are very common for process control equipment.

Increased Safety “Ex e”

The requirements for increased safety protection methods are written in the EN/IEC/UL 60079-7 standard. For "Ex e" equipment additional measures are adopted to afford a higher degree of safety. The methods are intended to prevent impermissible high temperatures and the occurrence of sparks and flashovers inside or on the outer parts of electrical equipment. "Ex ec" (non-sparking protection) is replacing the former type of protection "Ex nA" (non-arcing).

Increased safety devices can be used in:

- Ex eb Zone 1, 2

- Ex ec Zone 2

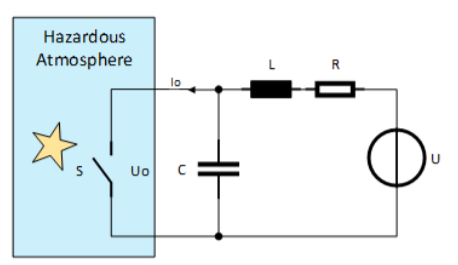

Intrinsic Safety (IS) “Ex i”

The requirements for intrinsically safe protection methods are written in the EN/IEC/UL 60079-11 standard. An electric circuit is intrinsically safe if no sparks or thermal effects are produced under normal operation and specific fault conditions. The protection method Intrinsic safety is limited to circuits that have relatively low levels of power. Intrinsic safety devices can be used in or can supply Ex i devices in:

- Ex ia Zone 0, 1, 2 and Zone 20, 21, 22

- Ex ib Zone 1, 2 and Zone 21, 22

- Ex ic in Zone 2 and Zone 22

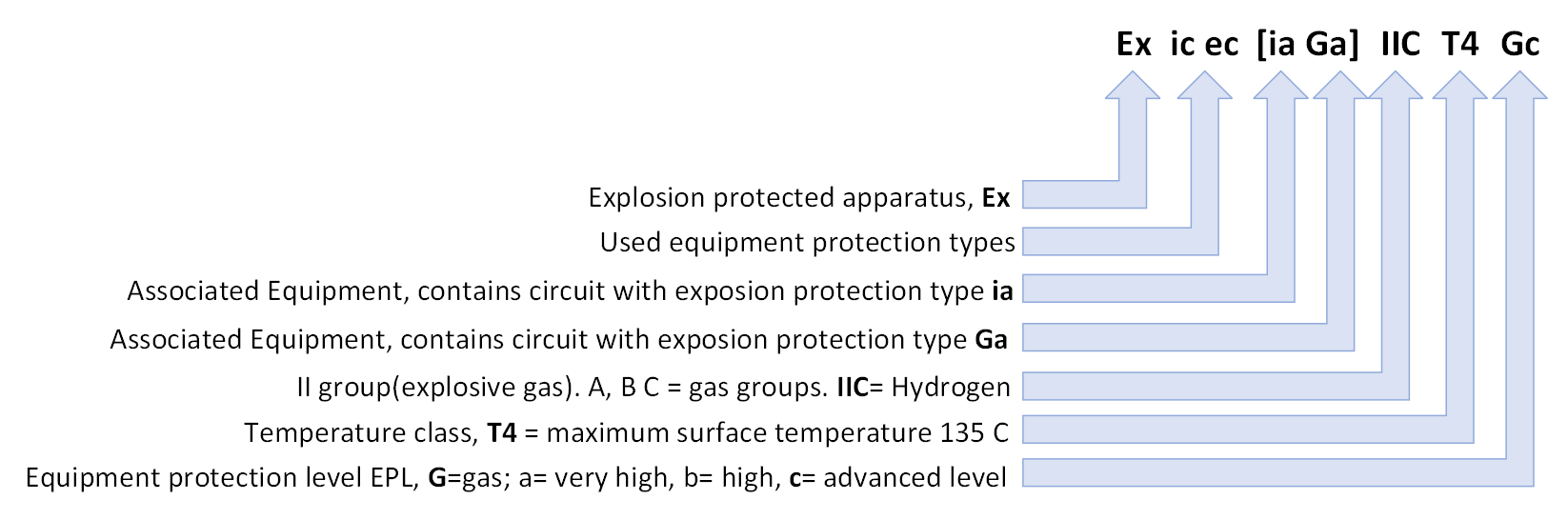

Marking

Marking according to EN-standards

World of standards

Several different standards cover explosion protection

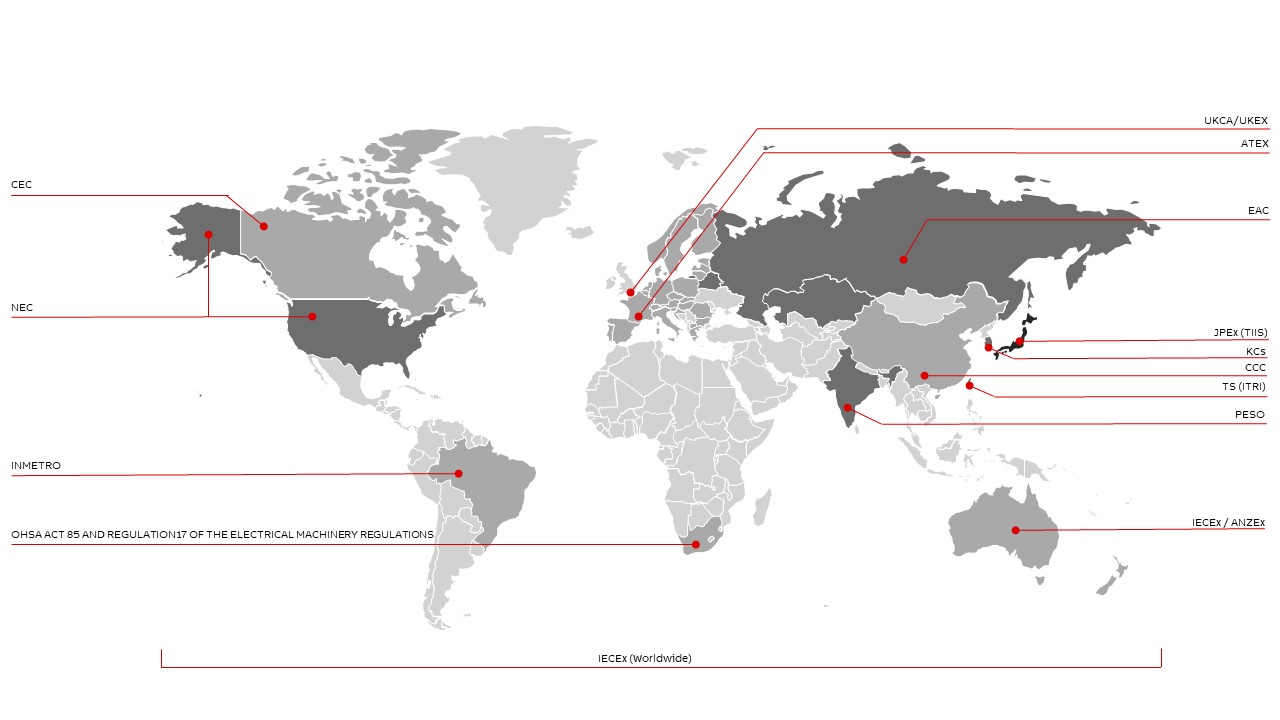

IECEx

The IECEx system (www.iecex.com) – from the International Electrotechnical Commission, is a voluntary certification system that verifies compliance with IEC standards related to safety in explosive atmospheres. IECEx covers four main areas:

- Certification of service facilities

- Equipment certification

- Ex marking conformity

- Certification of Personnel Competencies

IEC and EN standards

IEC: International Electrotechnical Commission, EN: European standard

- IEC 60050-426 Equipment for explosive atmospheres

- IEC/EN 60079-0: Equipment – General requirements

- IEC/EN 60079-1: Equipment protection by flameproof enclosures “d”

- IEC 60079-2: Equipment protection by pressurized enclosure "p"

- IEC/EN 60079-7: Equipment protection by increased safety “e”

- IEC/EN 60079-10: Classification of hazardous areas (gas areas)

- IEC 60079-10-1: Classification of areas – Explosive gas atmospheres

- IEC 60079-10-2: Classification of areas – Combustible dust atmospheres

- IEC/EN 60079-14: Electrical installations design, selection and erection

- IEC/EN 60079-15: Equipment protection by type of protection “n” (no longer applicable to rotating machines)

- IEC/EN 60079-17: Electrical installations inspections and maintenance

- IEC/EN 60079-19: Equipment repair, overhaul and reclamation

- IEC/EN 60079-31: Equipment dust ignition protection by enclosure “t”

European directives (ATEX)

Commonly referred to as ATEX, from the French “ATmosphères EXplosibles”, the European regulations combine two EU directives: the Worker Protection Directive (1999/92/EC) and the Product Directive (2014/34/ EU). The EU Directives have some differences from IECEx, and they do not include certification of service facilities or certification of personnel competencies. Compliance with the “Essential Health and Safety Requirements” described in the directives is mandatory within EU countries. The easiest way to show compliance is to follow harmonized standards.

- The Worker Protection Directive (1999/92/EC) specifies the minimum health and safety requirements for workers performing duties in potentially explosive atmospheres.

- The Product Directive (2014/34/EU) specifies requirements for equipment that is used in potentially explosive atmospheres. It also specifies the requirements for protective systems that are needed for equipment protection.

UKCA (UKEX)

UKCA marking (UKEX) is the UK product marking requirement that will be needed for all Ex products being placed on the market in Great Britain, substituting the EU requirements for CE Marking.

National Electric Code (NEC) and Canadian Electric Code (CEC)

NEC/CEC: National Fire Protection Association - National Electrical Code / Canadian Electric Code (500 or 505) in North America.

References

Related

- How-to Manage Bugs

- Pull Request Reference

- Cyber Security In User Documentation

- Security Testing Guideline

- How-to Perform Ex Internal Audits

- How-to Perform Internal Ex Trainings

- How-to Handle Ex Non-conformities

- How-to Perform Supplier Ex Audits

- Calibration of PAPCP REH Hardware Equipment

- How-to Manage Hardware Certifications

- Reference: What is an Approved Manufacturer List (AML)?

- Reference: Engineering Service Request (ESR) vs Engineering Change Order (ECO)

- Reference: Structure of Combitrol & Combimatic documentation

- Reference: High-speed design formulas

- How-to Manage Stop and Start Orders

- How-to Create a New Mechanics Design

- New Product Introduction (NPI)

- Reference: Considerations to make in PCB layout

- Reference: What does the Production Package contain?

- Tutorial: Creating schematics or Circuit diagrams

- How-to Handle Minor Hardware Revisions

- Reference: Handling of HW maintenance

- Hardware Development

- Explosion Protection

- Product Lifecycle Management in Windchill