L4 and Maintenance

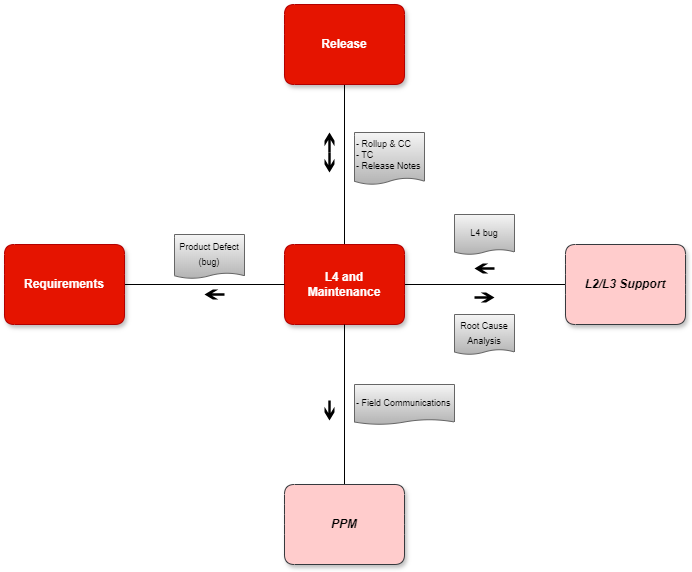

The process is mainly divided into two parts: continuous maintenance of existing products during the product life cycle, and an event-driven part handling both customer problems via Support Level 3 and manufacturing problems. The process covers both hardware and software.

Outputs from the process are rollups, certified corrections, temporary corrections, hardware revisions, field communications, resolution of customer-reported issues, etc.

Process Overview

Principles

-

L4 Support

- Collaborate with L2/L3 on customer cases requiring R&D support

- Analyze issues reported by customers and determine corrective actions

- Prioritize, and if needed to escalate, customer issues to respond in a timely fashion

- Communicate the status of the L4 bugs to stakeholders

-

Maintenance

- Initiate maintenance during the life-cycle of products and systems

- Write and publish field communication in collaboration with PPM

- Investigate and mitigate software vulnerabilities

- Investigate suspected malware in ABB software

- Initiate HW revisions related to:

- Design improvements and technical component issues

- Mitigating LTB and component sourcing issues

- Changed standards, and norms

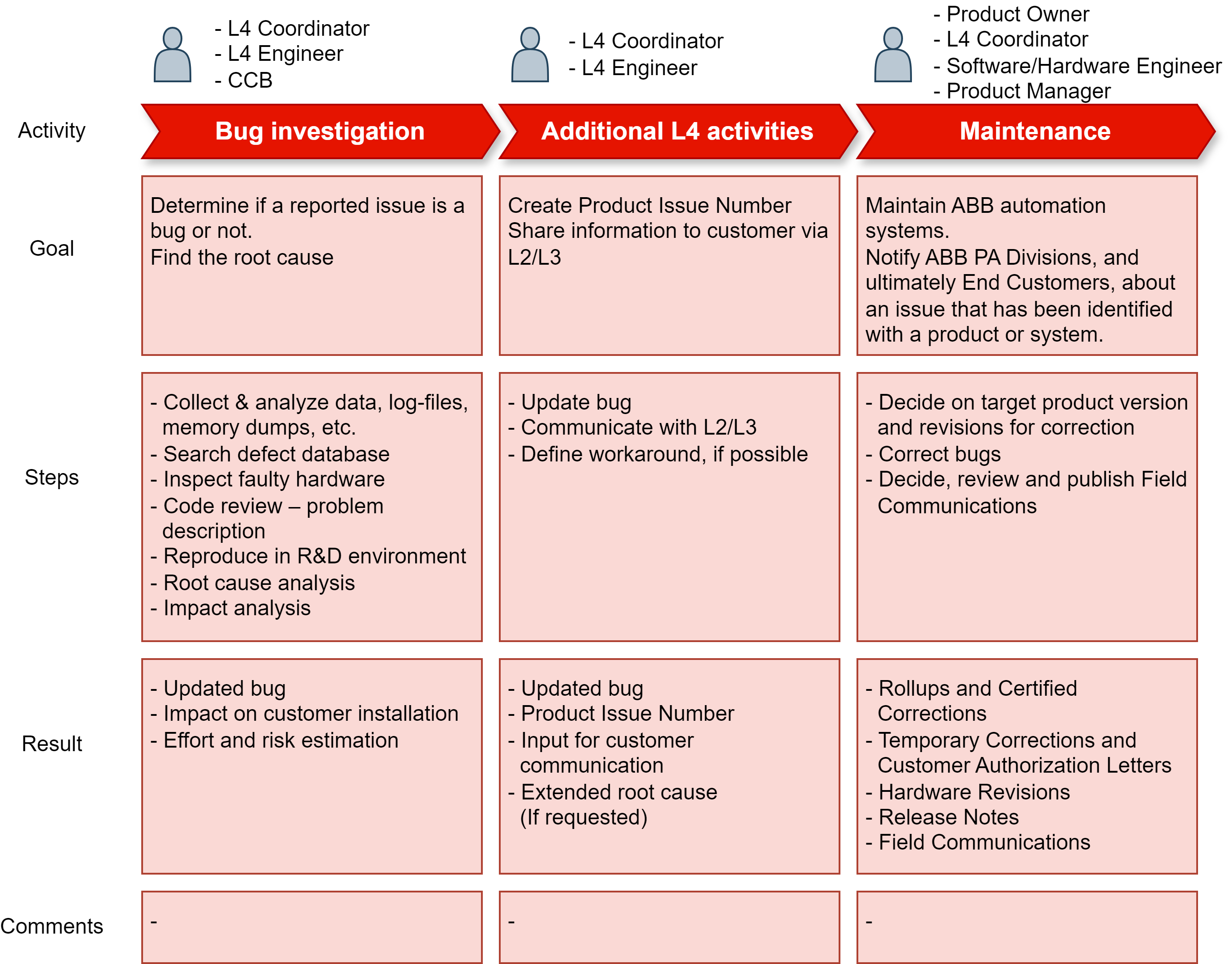

Activities

Artifacts

| Artifact | Description | RACI | Receiver | Comments |

|---|---|---|---|---|

| L4 Bug | Customer problem escalated to L4/R&D by Support Level 3 using a bug in Azure DevOps*). | (R): L4 Engineer (A): L4 Coordinator (C): - (I): - | Product Owner | - |

| Extended Root Cause Analysis | Description of the root cause analysis of an issues or bug requested by a customer. | (R): Dev. Team (A): Product Owner (C): - (I): - | L4 Coordinator | - |

| Temporary Correction | A Temporary Correction (TC) is intended for immediate correction of critical problems and are primarily intended for one or possibly a few end customers. Use the TC checklist to manage the correction. | (R): Product Owner, L4 Coordinator, Release Owner (A): Cluster Lead (C): - (I): - | R&D | - |

| Rollup | Can have a single correction, but it usually accumulates several corrections made available to all customer. Managed with the rollup checklist. | (R): Release Owner: (A): Stream Lead (C): - (I): - | R&D | - |

| Certified Correction | A certified correction (CC) is intended for immediate correction of problems in safety-certified products. Use the rollup checklist to manage the correction. | (R): Release Owner: (A): Stream Lead (C): - (I): - | R&D | - |

| Release Notes | Description of new features, corrected bugs, etc. in a release (TC and rollup). | (R): Product Owner (A): Cluster Lead (C): - (I): - | R&D | - |

| Customer Authorization Letter | Authorize the customer to install a temporary correction on a specific site. | (R): L4 Coordinator (A): L4 Coordinator (C): - (I): - | R&D | - |

| Field Communication | Used to notify ABB PA Divisions, and ultimately End Customers, about an issue that has been identified with a product or system. All Field Communications are published and distributed through the ABB Library and My Control System distribution portals. Note: The Field Communication process is owned by Product and Portfolio Management (PPM), see References below. | RACI information is specified in the PPM process | PPM | - |

Dependencies

References

- 2PAA125917 PAPCP Aftersales Support Case Processing Guideline

- 3BUL980146 Writing and Publishing Field Communication

- 3BSE059612 Certified Correction Handling 800xA Safety

Related

Owner: L4 and Maintenance Team