Hardware Development

Hardware development involves the design and manufacture of electromechanical devices. It includes CAD models, prototypes, manufacturing documentation, and certifications.

Process Overview

Principles

- Analyze and select hardware components based on performance, environmental and certification requirements, component obsolescence, manufacturability, and cost.

- Verify the solution in steps (simulations, 3D printed parts, mock-ups, proof of concept, prototypes).

- Demonstration of intermediate deliverables to key stakeholders for early feedback.

- Provide electrical, mechanical, and thermal design with appropriate simulations (virtual prototypes).

- Review the design to catch problems early on.

- Early integration and testing of hardware and software.

- Provide input for end-user documentation.

- Secure firmware deliveries to electronic manufacturing services (EMS).

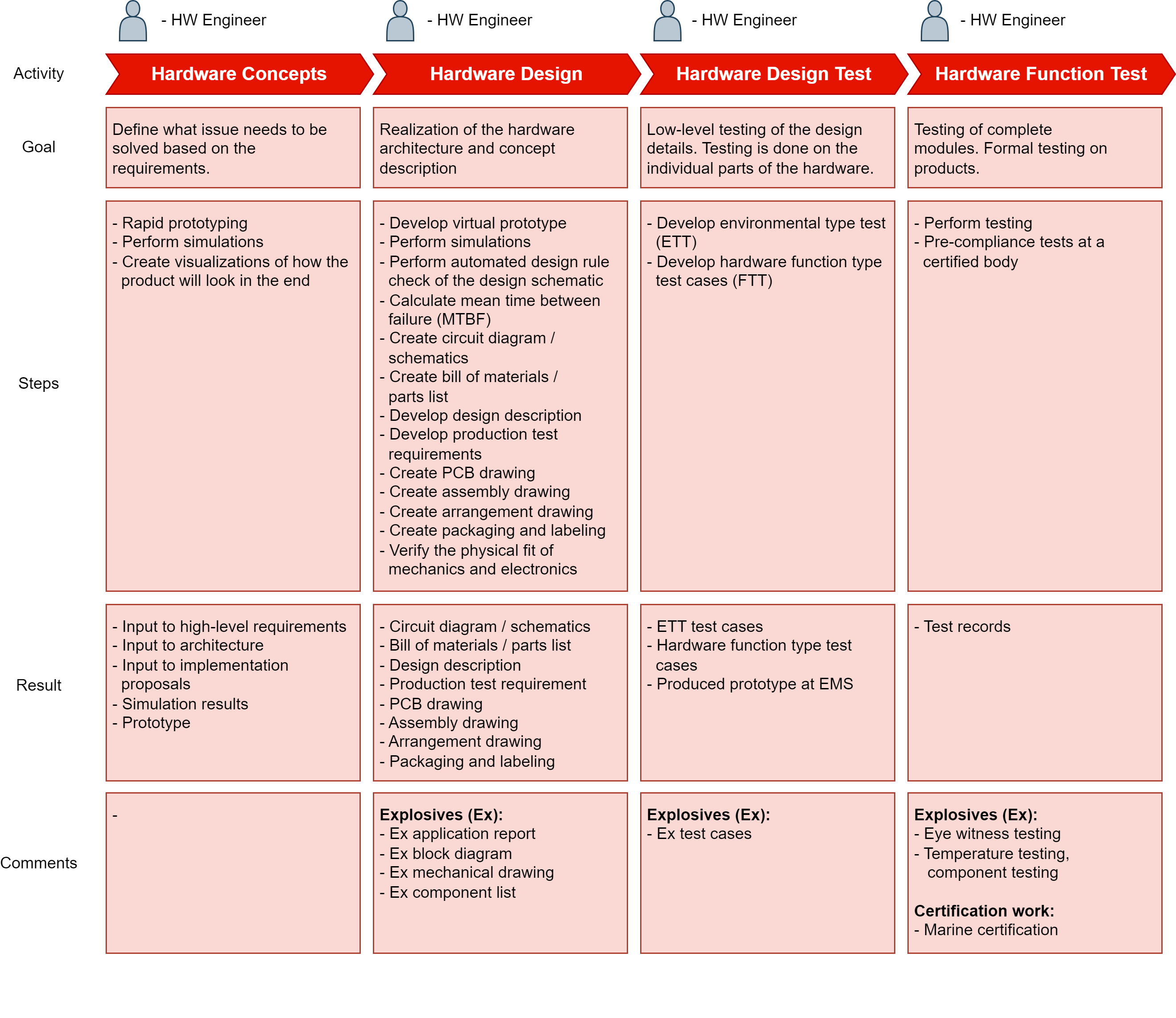

Activities

Artifacts

Artifact templates can be found under tools and templates. Note that the document subnumbers are primarily valid for 800xA and Advant.

- For document reviews use 3BSE052207 Formal Review Process Guideline.

- For explosive (Ex) designs the use of 3BSE028024 Checklist for Reviews is mandatory.

| Artifact | Description | RACI | Receiver | Comments |

|---|---|---|---|---|

| Arrangement drawing Document subnumber: D0004 | Component placement on Printed Circuit Board Assembly (PCBA) including not mounted components and coating areas. | (R): Development Team (A): Product Owner (C): Ex Component Responsible, Industrial Engineer (I): - | Electronic Manufacturing Services (EMS) | - |

| Assembly drawing Document subnumber: D0003 | Box assembly. Assembly sequence of all mechanical parts including PCBA. | (R): Development Team (A): Product Owner (C): Ex Component Responsible, Industrial Engineer (I): - | EMS | - |

| Bill of material or Parts list Document subnumber: no subnumber | Parts list: A list of items needed to manufacture a product. Bill of material: List of Customer Part Numbers (CPN) and associated Manufacturer Part Numbers (MPN). | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Configuration Manager, Industrial Engineer | EMS | - |

| CD (Circuit Diagram) or Schematics Document subnumber: D0002 | Graphical representation of an electrical circuit. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible, Safety Engineer (I): Industrial Engineer | EMS | - |

| Component specification | Describes the specifications of the Component. Mechanics: drawing with requirements on tolerances etc. Hardware: Document containing information about requirements on a component. | (R): Development Team (A): Product Owner (C): Architect, Development Team, Ex Component Responsible, Safety Engineer (I): - | EMS and Manufacturer of part | |

| DD (Design Description) Document subnumber: D0070 | Additional text description to the Circuit Diagram (CD). | (R): Development Team (A): Product Owner (C): Architect, Cyber Security Engineer, Development Team, Ex Component Responsible, Safety Engineer (I): Quality Control Manager | R&D | - |

| DD (Design Description) Printed Circuit Board (PCB) mechanical Document subnumber: D0071 | This is the mechanical drawing for the PCB. It is also known as an obstruct drawing. 3D model. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible, Safety Engineer (I): - | R&D | - |

| ETTD (Environmental Type Test Description) Document subnumber: D0041 | Test cases under different environmental conditions, humidity, temperature, pressure, etc. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Safety Engineer | Operations | - |

| ETTR (Environmental Type Test Record) Document subnumber: D0051 | Result of the Environmental Type Test (ETT). | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Safety Engineer | Operations | - |

| Ex application report Document subnumber: D903x | Report that is sent to the certifying body for certification. | (R): Ex Component Responsible (A): Product Owner (C): Development Team, Ex Representative (I): - | Notified body | Only for Ex certified products |

| Ex block diagram Document subnumber:D902x | Simplified block diagram which contains items relevant for Ex certification. | (R): Ex Component Responsible (A): Product Owner (C): Development Team (I): Ex Representative | Notified body | Only for Ex certified products |

| Ex component list Document subnumber:D9400 | Component list that contains items relevant to Ex certification. | (R): Ex Component Responsible (A): Product Owner (C): - (I): - | Notified body | Only for Ex certified products |

| Ex mechanical drawing Document subnumber:D9403 | Simplified mechanical drawing which contains items relevant for Ex certification, is sent to the certifying body. | (R): Ex Component Responsible (A): Product Owner (C): Development Team (I): - | Notified body | Only for Ex certified products |

| Ex type test record Document subnumber:D92xx | Records the result from the Ex type test. | (R): Ex Component Responsible (A): Product Owner (C): Ex Representative (I): - | Notified body | Only for Ex certified products |

| Ex label drawings Document subnumber:D914x | Simplified Label drawing, which contains the Ex relevant information for product certification. | (R): Ex Component Responsible (A): Product Owner (C): Development Team (I): - | Notified body | Only for Ex certified products |

| Ex PCB drawing Document subnumber:D9040 | Simplified PCB/Layout drawing, which contains Ex relevant information for product certification. | (R): Ex Component Responsible (A): Product Owner (C): Development Team (I): - | Notified body | Only for Ex certified products |

| FTTD (Function Type Test Description) Document subnumber: D0042 | Test of the hardware. | (R): Development Team (A): Product Owner (C): Cyber Security Engineer, Development Team, Ex Component Responsible, Safety Engineer (I): - | R&D | - |

| FTTR (Function Type Test Record) Document subnumber: D0052 | Result of the test. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible, Safety Engineer (I): - | R&D | - |

| Inspection provision Document subnumber: D0021 | Factory work instruction how test is performed. | (R): HW engineer (A): Product Owner (C): Ex Component Responsible (I): - | EMS | - |

| Marking data | Describes the content of the label. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Industrial Engineer | EMS | - |

| Marking placement | Drawing for the label location on the product. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Industrial Engineer | EMS | - |

| Label for package | Drawing for the label location on package. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Industrial Engineer | EMS | - |

| Label for bag | Drawing for the label location on the bag. Note: for products that do not have a PCB. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Industrial Engineer | EMS | - |

| Packaging | Describes the packaging of the product. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Industrial Engineer | EMS | - |

| PCB Layout | Detailed PCB design. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Safety Engineer, Industrial Engineer | EMS | - |

| Product approval Document subnumber: D0096 | Product approval shall be made before production on a sample from the manufacturer that represents the series production. Note: This is dependent on the production site so each site needs a separate product approval. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible (I): Safety Engineer | EMS | - |

| Production Package | A set of files needed for production. | Please see Production Package. | EMS | - |

| Production test requirements (PTRs) or factory test instruction Document subnumber: D0029 | Describes the requirements that the EMS need to meet. | (R): Development Team (A): Product Owner (C): Development Team, Ex Component Responsible, Industrial Engineer (I): Safety Engineer | EMS | - |

| Input to User doc | User documentation describing the functionality from a user perspective. | (R): HW engineer (A): Product Manager (C): Ex Component Responsible (I): - | Product Manager, Test Team, User | - |

- Note: Cyber security, safety, and Ex roles should be considered when applicable.

- Note: For CCC (China Compulsory Certification) certified products the Ex component responsibile shall involve the CCC Ex technical representative as well.

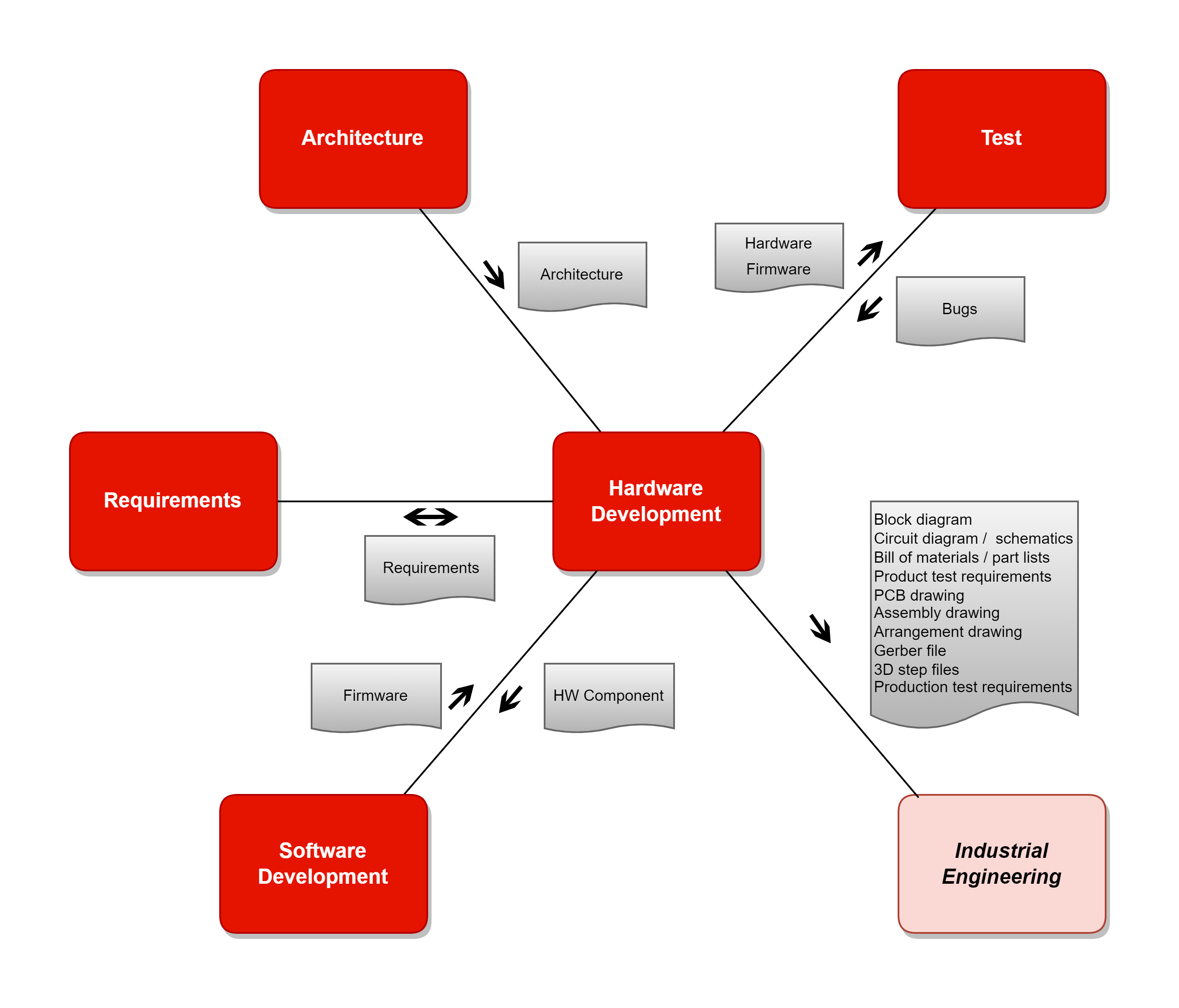

Dependencies

References

Related

- How-to Manage Bugs

- Pull Request Reference

- Cyber Security In User Documentation

- Security Testing Guideline

- Calibration of PAPCP REH Hardware Equipment

- How-to Manage Hardware Certifications

- Reference: What is an Approved Manufacturer List (AML)?

- Reference: Engineering Service Request (ESR) vs Engineering Change Order (ECO)

- Reference: Structure of Combitrol & Combimatic documentation

- Reference: High-speed design formulas

- How-to Manage Stop and Start Orders

- How-to Create a New Mechanics Design

- New Product Introduction (NPI)

- Reference: Considerations to make in PCB layout

- Reference: What does the Production Package contain?

- Tutorial: Creating schematics or Circuit diagrams

- How-to Handle Minor Hardware Revisions

- Reference: Handling of HW maintenance

- Hardware Development

- Explosion Protection

- Product Lifecycle Management in Windchill

Owner: Hardware Development Team