Reference: Handling of HW maintenance

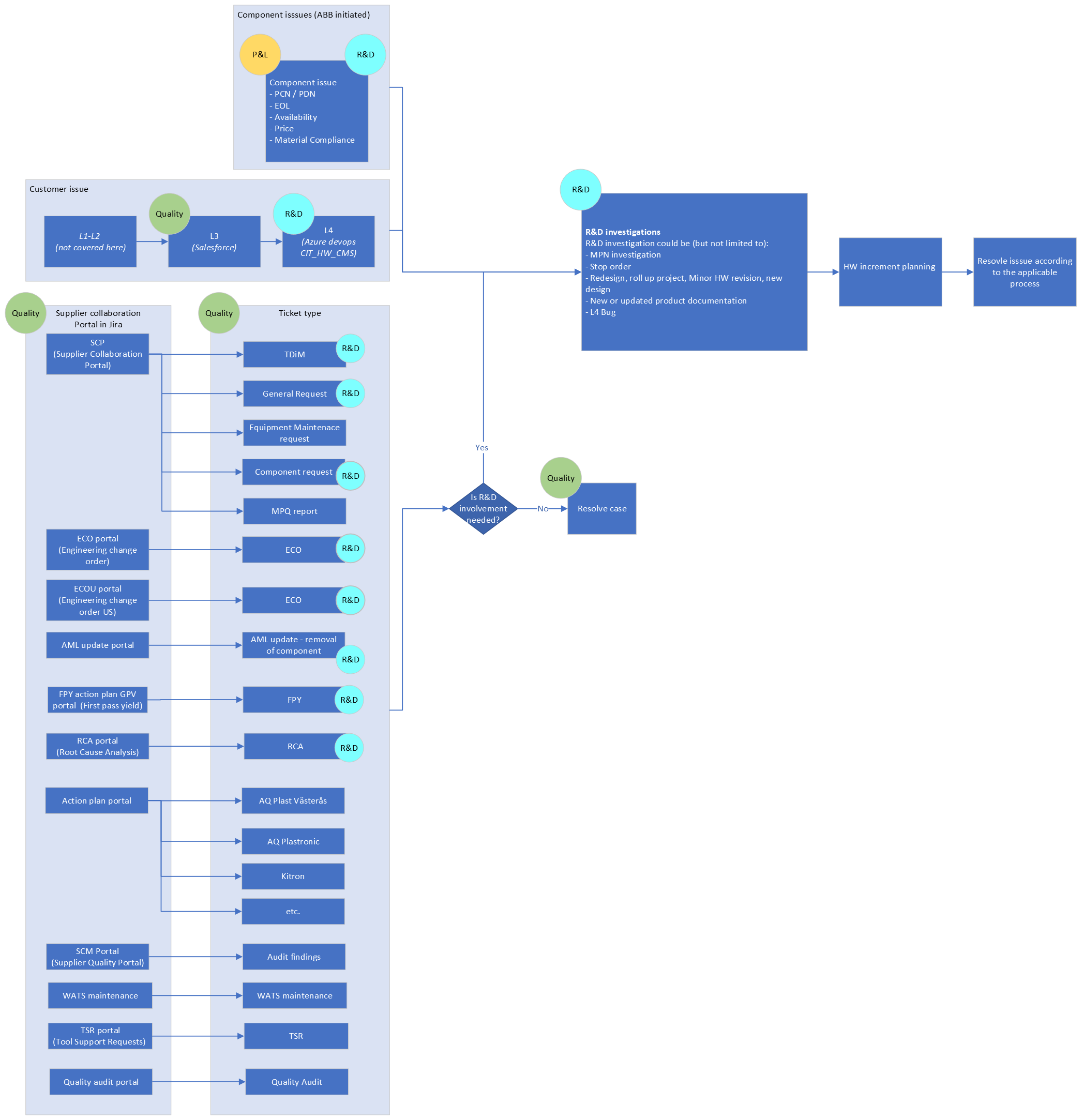

Hardware development has a lot of interactions with internal ABB functions and external suppliers, manufacturers, and customers. This page is intended to give an overview of how maintenance tasks come to the R&D Hardware teams.

Overview

There are three main areas from which hardware development can receive maintenance tasks.

- Component issues

- Customer issues

- Supplier issues (collaboration)

Legend

Circles indicate involvement.

- P&L Component Managers are responsible for monitoring components and working strategically with components. This team needs to have continuous contact with R&D Component Engineers.

- L3 (Quality) and L4 (R&D HW) need to have contact to enable a smooth transition between L3 and L4 cases.

- The collaboration with suppliers is overseen by Quality (Industrial Engineering or Supplier Quality Managers). They act as a first line and assign tickets to persons within R&D when necessary. In the image above the R&D, circles are present on the types of tickets that are most common for R&D engineers.

Once R&D has taken the cases then we are responsible for seeing them to the end so that they can be closed.

Component issues

Issues regarding components are monitored by component engineers and the component management team within P&L. P&L can raise issues with R&D when there is a need to remove or add manufacturer part numbers (MPNs) from the Approved Manufacturer list (AML). These requests result in MPN investigations which is a process where hardware developers assess the impact of the change on each product that has this specific component. Click here for more information on the AML

Customer issues

If a customer finds a fault in a product this can be reported to ABB support functions near our customers L1 and L2. If the problem is more difficult to solve then it will become an L3 case which in some cases becomes an L4 case and is then analyzed and handled by hardware developers.

Supplier collaboration

Industrial Engineering is responsible for administrating Jira. Jira is a system that is the preferred way of communicating with suppliers or manufacturers. With this tool, we have full traceability of communication and commitments made by our suppliers or manufacturers. This is important when investigating or during audits.

Link to Jira: Please click here Jira

For access requests to Jira: please place a ticket here TSR however this needs to be done by someone who already has access. If the link cannot be used please contact Industrial Engineering (martynas.gedgaudas@lt.abb.com).

All communication between ABB and suppliers or manufacturers shall be handled through the tool Jira. This tool is a tracking system that enables communication between internal ABB functions as well as the suppliers and manufacturers. There are 11 different portals in Jira that contain different kinds of tickets. The 5 portals are:

- SCP: Supplier Collaboration Portal Here a wide range of tickets are available.

- TDiM: Temporary Deviations in Manufacturing. Manufacturers report TDiMs when there is a need to temporarily approve a component or procedure.

- General request: This can be any sort of request that does not fit in the other ticket types.

- Equipment Maintenance request: Request from supplier or ABB that maintenance is needed on ABB owned equipment. Usually, R&D involvement is not needed.

- Component request: This is used when the supplier sees the need for an updated AML due to component shortage etc.

- MPQ report: Manufacturing Process Qualification. Communication channel with the supplier regarding the MPQ report. In general, R&D is not involved here.

- ECO portal: Engineering change order portal This is used when Engineering change orders are placed with the manufacturer or supplier. R&D registers the ECO and is one of the approvers of the quotation.

- ECOU portal: Engineering change order portal for the US

- AML update portal: Approved manufacturer list portal This is used when there is a critical component that needs to be removed from the AML but we want to also oversee the current stock of the component to make sure that there is a smooth transition.

- FPY action plan GPV portal This is a test project for the improvement of FPY (First Pass Yield). As of now R&D is not highly involved but will probably be in the future. This will also probably be present at all suppliers or manufacturers in time.

- RCA portal (Root Cause analysis portal) This project is used for customer funded Root Cause Analysis investigations when warranty does not apply anymore and L4 is not used. It is available upon request where R&D accepts if there is time to handle this. Please see this document for more information Distributed Control Systems - LifeCycle Parts Services, 3BSE065503. Usually, these items originate from the Services department in Malmö.

- Action plan portal There are individual action plans for each supplier. Here the tickets can be improvements that are not found in an audit. Generic for running production planning.

- SCM Portal: Supplier Quality Portal This is where the SQM team reports findings from audits of the suppliers. These are then monitored and resolved between the SQM team and the supplier.

- WATS maintenance. Items related to Wats maintenance.

- TSR portal (Tool Support and Request portal) This is a ticket type for improvement suggestions to the Jira tool. Also, place access requests in this area, TSR.

- Quality audit portal Items for internal audits found for instance in an ISO 9001 audit.

For any of these tickets, there might be a need to collaborate between R&D and Operations to come to a solution. In the below image, the circles indicate which items often involve R&D resources.

R&D investigations

The outcome of any of these cases needs to be allocated R&D resources. This is done in the increment planning. Any of these inputs could give any of the outputs listed in the below sections.

MPN investigation

MPN (Manufacturer Part Number) investigation is used whenever a new component is requested to be added or removed from the AML (Approved Manufacturer List). MPN investigations check if the component that will be added or removed has any effect on the current design in which this component is used. Which products are affected by the change in this CPN (abb number, Customer Part Number) is found by doing a "where used" search. Product owners for the relevant products are involved and will approve the new components after the investigation has been completed. The extent of the MPN investigation can be anything from comparing data sheets to doing tests with the new component.

Stop order

If a serious defect in a product is detected, and it is considered so serious that the units cannot be delivered in their present state, the units must be prevented from being delivered immediately. This is done with a stop order. For details please see Stop order

Redesign

For some issues, the best solution is to make a redesign of the product. Depending on the scope, time and budget aspects different kinds of projects can be used.

New or updated product documentation

Within R&D and hardware, we maintain products that were released in the 1960's. In the case that we would need to create a new tester for this product then we might have to gather new documentation about how the old tester worked.

L4 cases

When L3 support (level 3) needs help then L4 support kicks in. This means an investigation from R&D is started and bugs are reported to track the work. Please see How To Handle a Product Issue for more information.