How-to Handle Minor Hardware Revisions

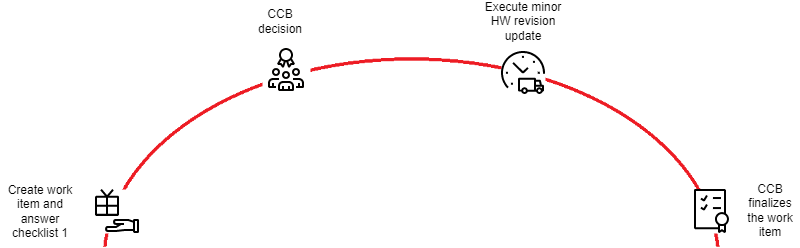

Some minor hardware changes to products can be implemented without setting up a project. This guide describes the steps involved and the checklists that shall be used.

Intended for

Product owners or a person coordinating minor hardware revisions.

Activities

Create a work item and answer checklist 1

Create a feature in Azure DevOps (other work item types could be used, please see How-to Work with Features).

- Add a title: “[Product name] - Minor HW revision”

- Add Checklist 1 to the description of the work item, and answer the questions in the checklist.

- Add Checklist 2 to the description of the work item. To be used during completion.

- Area path: maintenance area of the product.

- Assigned to: CCB

CCB decision

If ok to move ahead with the minor hardware revision process, set the following fields:

- State: "In progress".

- Assigned to: the person who is responsible for the implementation.

Execute minor hardware revision update

The person responsible for the implementation is typically the product owner. This person coordinates work and assigns tasks to the relevant people. The person responsible ensures that all items on Checklist 2 have been dealt with during the project. When all items in the checklist have been filled in, return it to the CCB.

- Assigned to: CCB

CCB finalizes the work item

The CCB reviews the checklist and checks that all items are acceptable.

- State: "Done"

If the feature for some reason can not be completed, the CCB shall set the state to "Removed".

Details

Copy and paste the checklist questions below into the work item when an update has been identified as a candidate for a minor hardware revision update.

Checklist 1

These questions are to be answered before the CCB can take a decision. If the answer to any question is yes, then a minor hardware revision process can not be used, and this work item shall be removed.

- Are there any changes to the intended functionality of the product?

- Do any of the corrections have an impact on other products in the system?

Checklist 2

Export control

If any question is answered with yes, then consult with the trade compliance officer: OnePoint - Trade compliance.

- Has the change included new components with the U.S. as the country of origin?

- Have any changes to integrated 3rd-party or software items originating from ABB U.S. been made in the product?

- Have any changes to redistributed 3rd-party or software items originating from ABB U.S. items been made in the product?

Security

- Has there been any changes in a component or function that is security critical? If yes, contact your cyber security engineer and discuss what is needed.

Examples of changes that should lead to a "yes" include:

- New/revised Ethernet controller (affects a security-critical component).

- New crypto chip.

- New/changed network switch component.

Certification preparations

List all certificates that are relevant to the product.

| Certificate | Impact of change (add explanation to your answer) |

|---|---|

| CE | |

| UL | |

| ATEX | |

| IECEx | |

| Safety | |

| <add applicable certificates> | |

| <add applicable certificates> |

- If any of the above certificates are affected, consult the person responsible for the certificate to get the necessary certification activities in place.

- The impact analysis report should be initiated.

Certification documents

- Have signed certificate(s) or annex (Safety) been received?

- If not, have all required documents been accepted by the assessor (at the notified body)?

- Has the correct product manager been informed about the updated certificate(s)?

- Is the updated certificate(s) published in the ABB library?

Environmental aspects

- Are material compliance requirements considered? For instance, SVHCs, RoHS (China and EU)?

Branded products

Some products are sold as a branded product.

-

Does the change affect the physical appearance of the branded module? If yes, list the modules affected.

Example: "PM891 is also sold as CPU80 and some modules are sold as -AE(AI810-AE)".

If the changes affect the physical appearance and are sold as a branded product, then contact the product owner responsible for the branded product.

Master data

- Update fields in the go-to-market template (GTMT) for the correct product family where "Product Specialist" is responsible.

Productization

-

Is product user documentation such as release notes etc. published?

-

Have electronic manufacturing services (EMS) received the updated product data? Consider a product that can be manufactured at several EMS sites.

-

Has the product approval test(s) been passed? Consider a product that can be manufactured at several EMS sites.

-

Have all support functions been contacted for relevant updates (P&L, P&F, SQE, IE, etc.)?

-

Is there a need to update a stop or start order?

-

Is there any open temporary deviation in manufacturing (TDiM) that can be closed after this update? If yes, list them.

-

Is the "Version in Use" document updated: 3BSE044322 Version in Use?

-

Is the "Version Specification" updated?

Example: for S800 this is a document with the sub-number D0099.