Reference: What does the Production Package contain?

A production package is created for every product and is the basis for a manufacturer. A production site is commonly called an electronic manufacturing service (EMS). This list is used by the EMS to create the product (box build).

Intended for

Hardware engineers, software engineers, configuration managers

Overview of production-related files

| Category | EMS | Artifact | Purpose of document | File type | Where is it stored? | How is it reviewed and approved? | Example |

|---|---|---|---|---|---|---|---|

| Components | GPV | Parts list | List of all components or ref. to other Parts lists for subassemblies manufacturing List of documents related to manufacturing. For many products, this is created by GPV. The Bill of Materials (BOM) is a part of it. | DMS | According to RACI | - | |

| Components | Avnet | BOM | List of CPNs and associated MPNs | Depends on product line | Depends on product line | According to RACI | - |

| Components | GPV AOD/SAP | Approved manufacturer list (AML) also known as an approved vendor list (AVL) | AML: For 800xA, Advant and Combitrol & Combimatic the AML are maintained by the component engineer team in Västerås. Updated once a week AVL: For products maintained in AOD this is handled through the tool | AML: .xls AVL: in AOD | AML: DMS AVL: NA | NA | - |

| Mechanical design | All | Assembly drawing (included in the parts list) | Assembly instruction and position of components and parts of the total product | DMS | According to RACI | - | |

| Mechanical design | All | Component specifications | Mechanical specification including tolerances etc. | DMS | According to RACI | - | |

| Mechanical design | All | 3D step files | Standard for exchange of product Data (STEP). ISO standard. Used to distribute 3D data files in a format that can be used in a variety of applications. | .step | NA | NA | - |

| Mechanical design | All | Label information Content | What needs to be on the label, drawing indicating exact text, letter size, data matrix code (DMC) format, whatever else, when it comes to what to be marked created in CAD software This is currently not created in a specific document and which document depends on the product line. Consult the mechanics team for more information. | - | - | - | - |

| Mechanical design | All | Label information location | Where on the product/package the label will sit. Created in CAD software This is currently not created in a specific document and which document depends on the product line. Consult the mechanics team for more information. | - | - | - | - |

| Mechanical design | All | Label information specification | Specification of label type, material, size. Created in CAD software This is currently not created in a specific document and which document depends on the product line. Consult the mechanics team for more information. | - | - | - | - |

| Mechanical design | All | Packing requirements | This is a CAD model of the product which we send to a packing company as a base of the design of the product package. | CAD file | DMS | This item is owned by the company that creates the packing reviewed with them. | - |

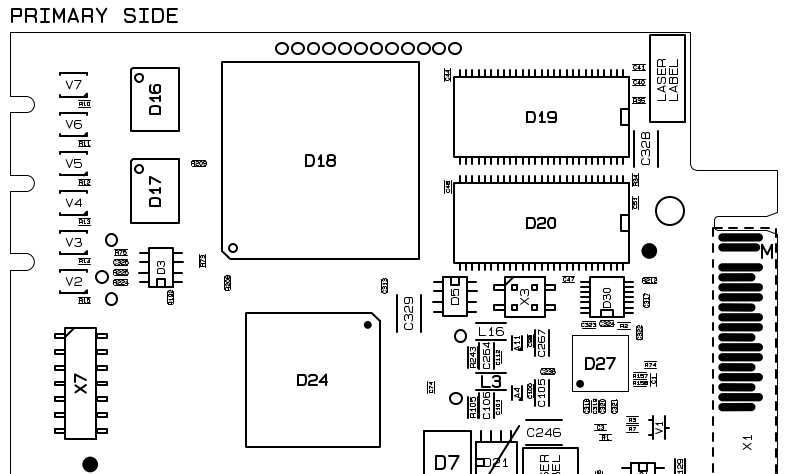

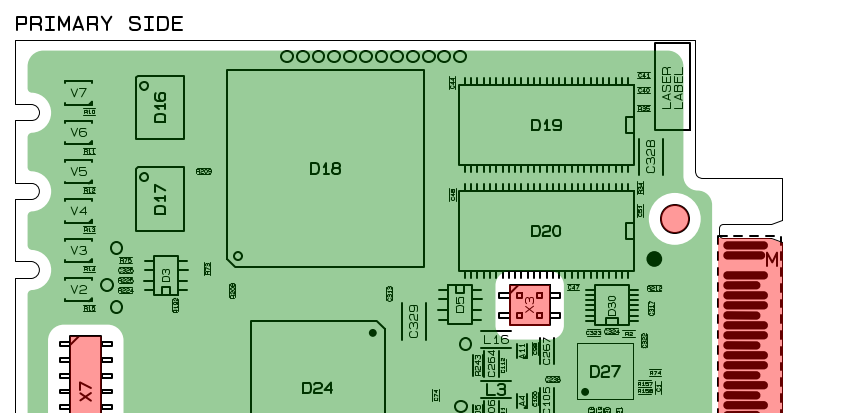

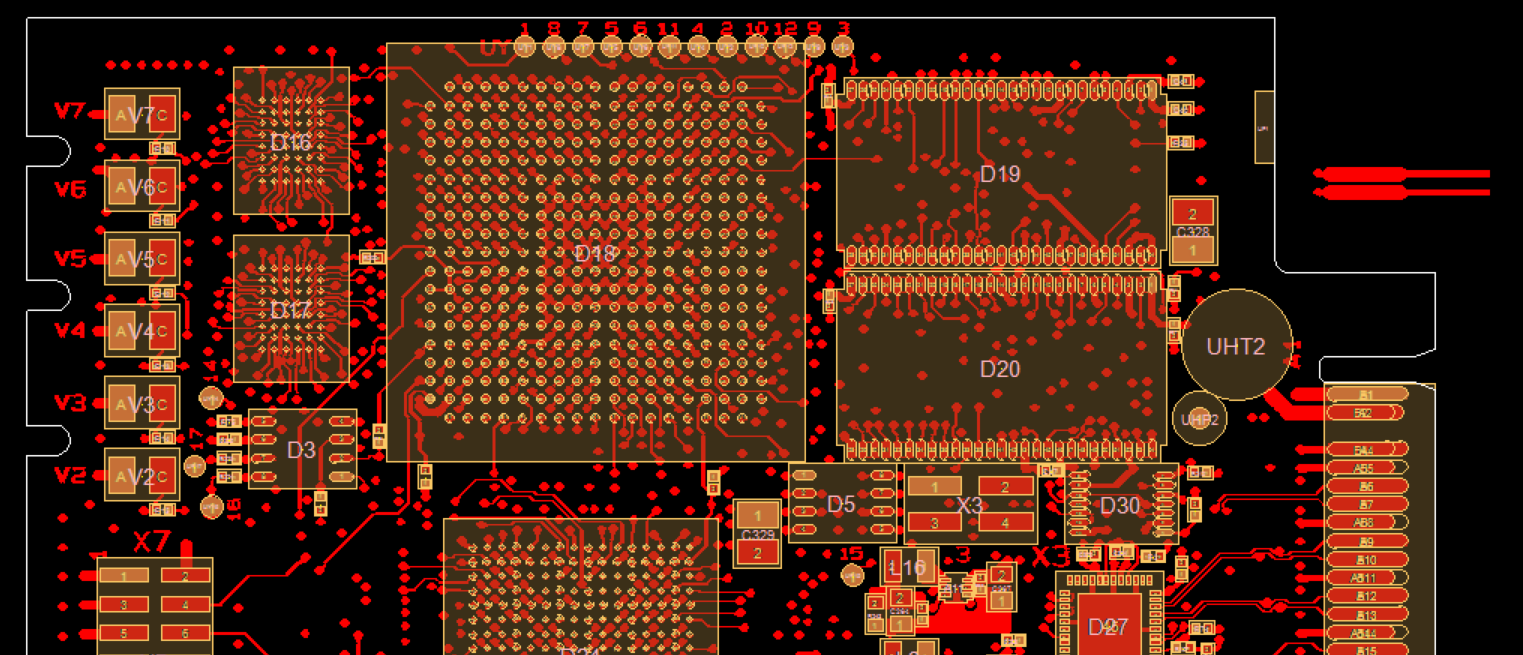

| Hardware design | All | Arrangement drawing (Sweden, Hangzhou), also called assembly drawing (Germany) | Drawing of the component placements on top and bottom side of the printed circuit board (PCB), also containing the coating areas in case of designs done at GPV. | DMS | According to RACI |   | |

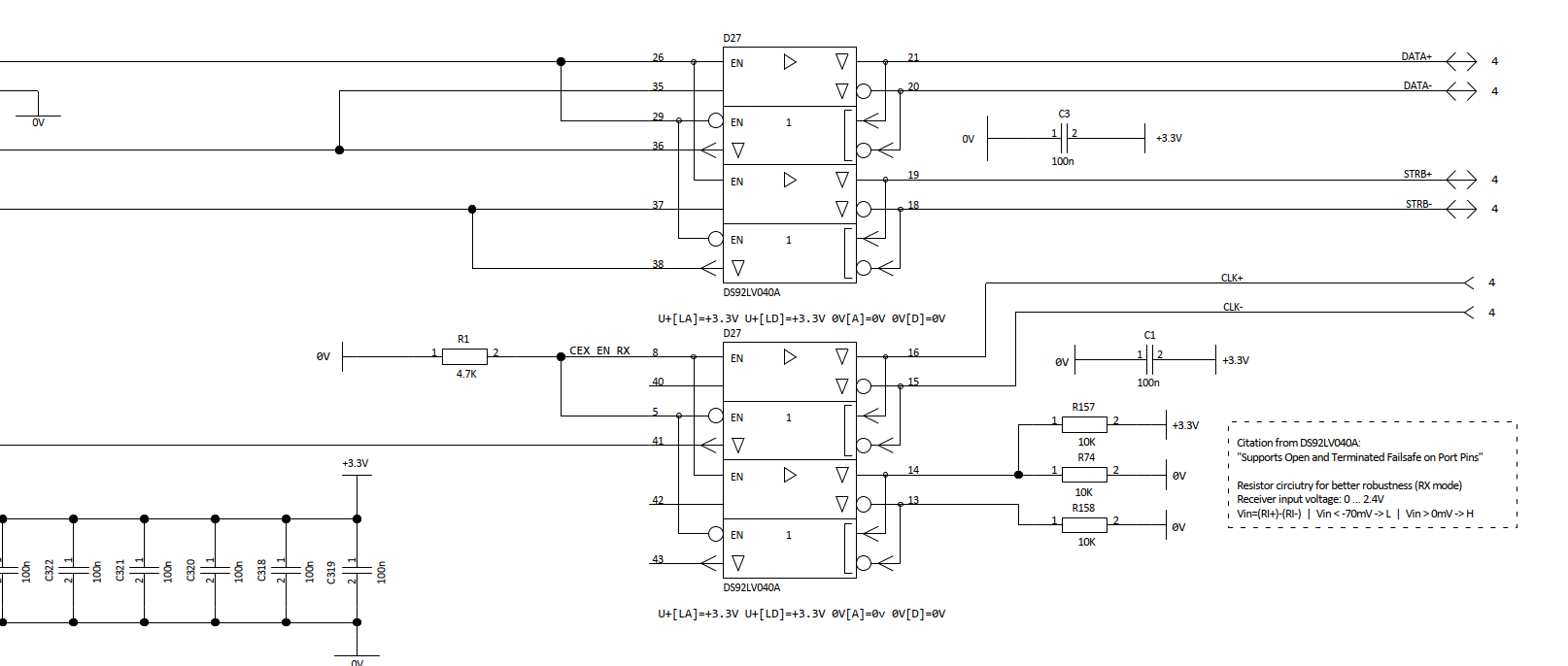

| Hardware design | All | Circuit diagram (Sweden, Hangzhou), also called schematics (Germany) | Electrical connections diagram, defining interconnections between components. Input document for PCB layout | DMS | According to RACI |  | |

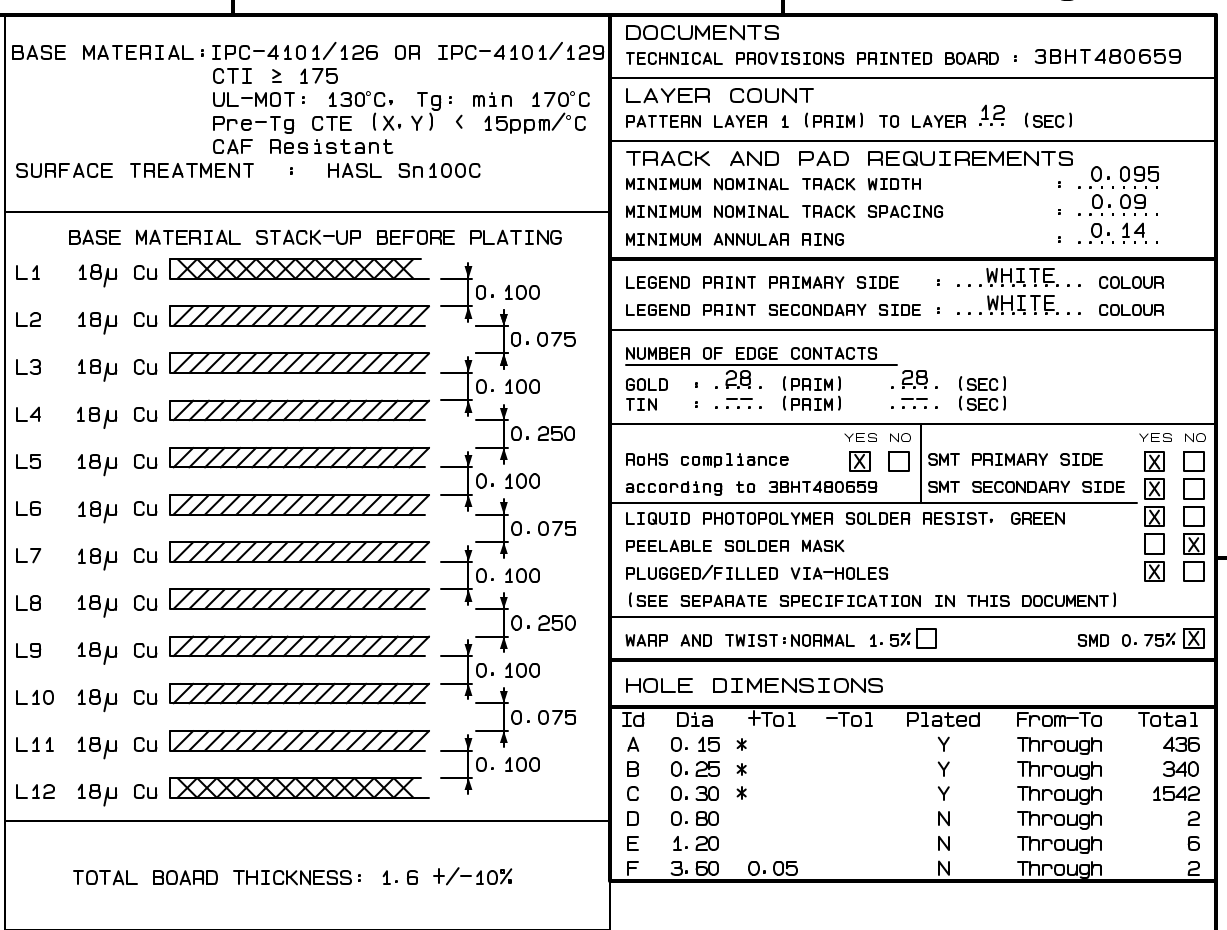

| Hardware design | All | PCB specification | Specification document for PCBs. 7PAA005857 replaces the old doc 3BHT480659. The focus is on the production quality of bare PCBs, based on IPC standards. Technical specification for Printed Circuit Boards, 7PAA005857 | .docx or .pdf | DMS | Process document | - |

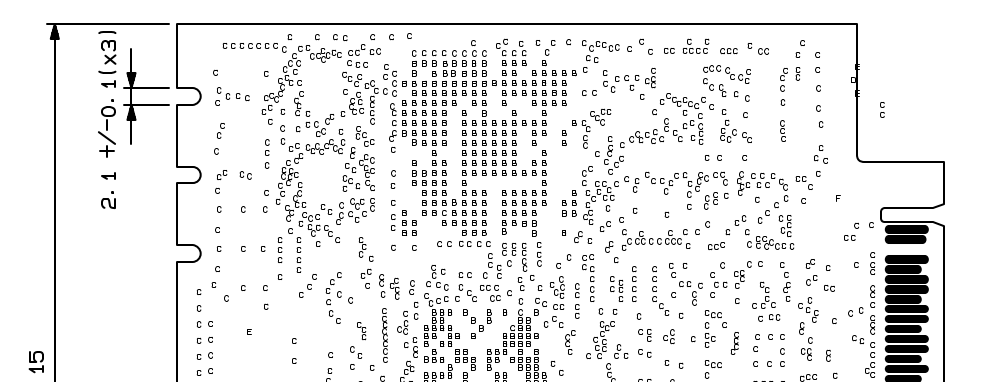

| Hardware design | All | Detail drawing Printed Board (Sweden, Hangzhou), also called PCB drill drawing (Germany) | Detailed drawing of the PCB with dimensions, including drill information for vias and mounting holes (hole sizes and positions) and the layer stackup. Includes references to PCB specification. Sometimes additional pages are added to show each copper layer (especially for ATEX certifications). This is a document created by an electronic manufacturing service or ABB hardware team. Contains the stack and the specifications for each electronic layer | DMS | (R): HW engineer (A): Product Owner (C): HW team (I): Industrial Engineer |   | |

| Hardware design | All | ODB++ files (more detailed than Gerber) | ODB:Open Data Base. Newer exchange format for PCB/PCBA data, including a whole folder structure compressed to an archive. Includes all relevant information required to produce an electronic module (copper layers, layer stackup, component placement, netlist, CPNs per reference designator). Only AML information is not included. Used by Avnet Embedded (MSC) as input for manufacturing end test, especially in case of Boundary Scan. Can fully replace Gerber, NC Drill, and Pick&Place files. The high-speed signal simulation tool Siemens HyperLynx can use this format as input to perform signal integrity simulations based on the actual layout. | .zip (container of information) or .tgz | DMS | By Industrial Engineer |  |

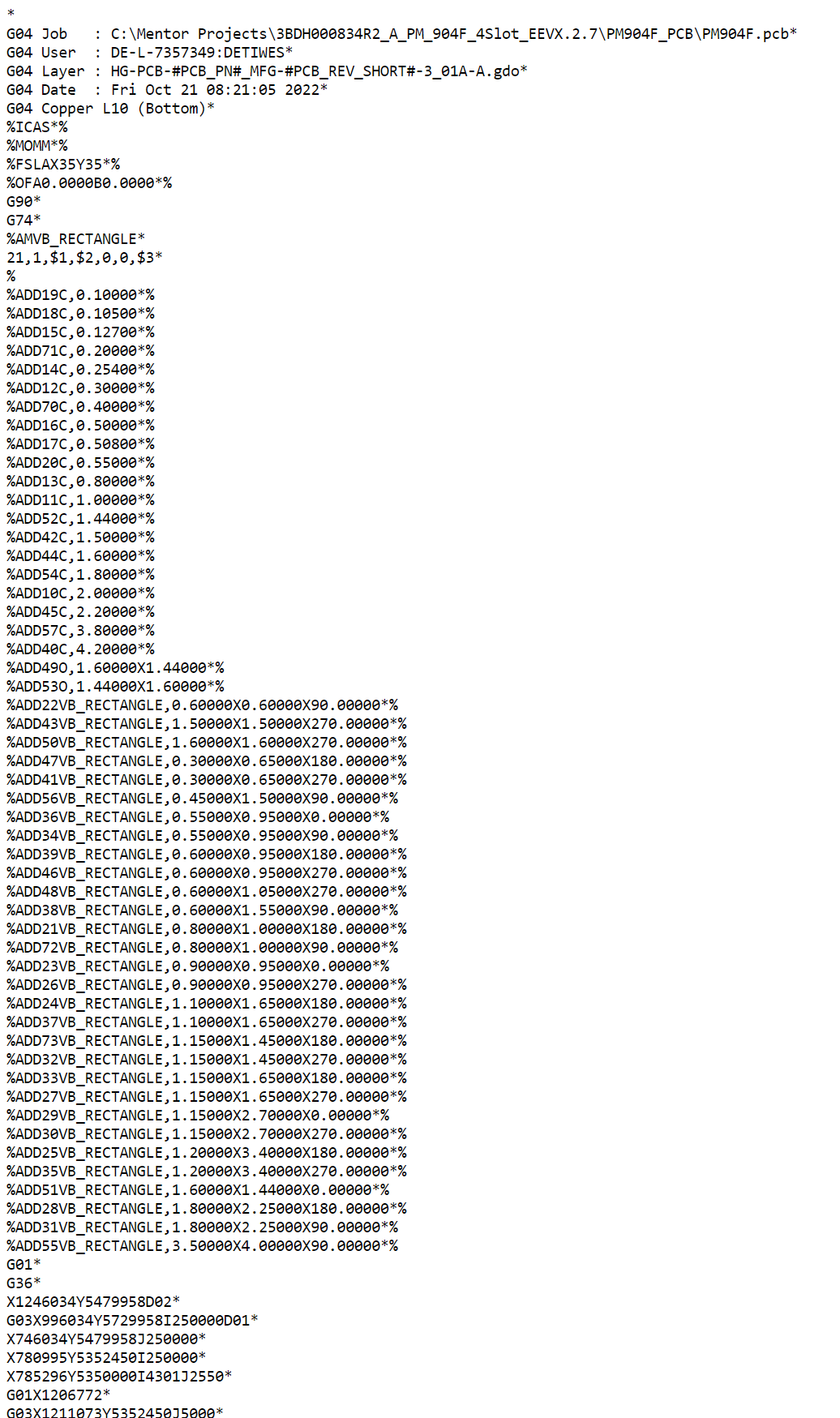

| Hardware design | All | Gerber | Standardized exchange format to PCB manufacturers to describe the PCB details (copper structures, soldermask, solderpaste). Each copper layer, each soldermask layer, and solderpaste side is documented in a separate file. Today's industry standard is “Extended Gerber RS-274-X”, which replaced the obsolete “Standard Gerber RS-274-D”. The files in general are ASCII files that describe the copper structures by coordinates. Imported to manufacturing machines at PCB manufacturers | GBR, GBO, … (file extension not fixed) | DMS | By Industrial Engineer |  |

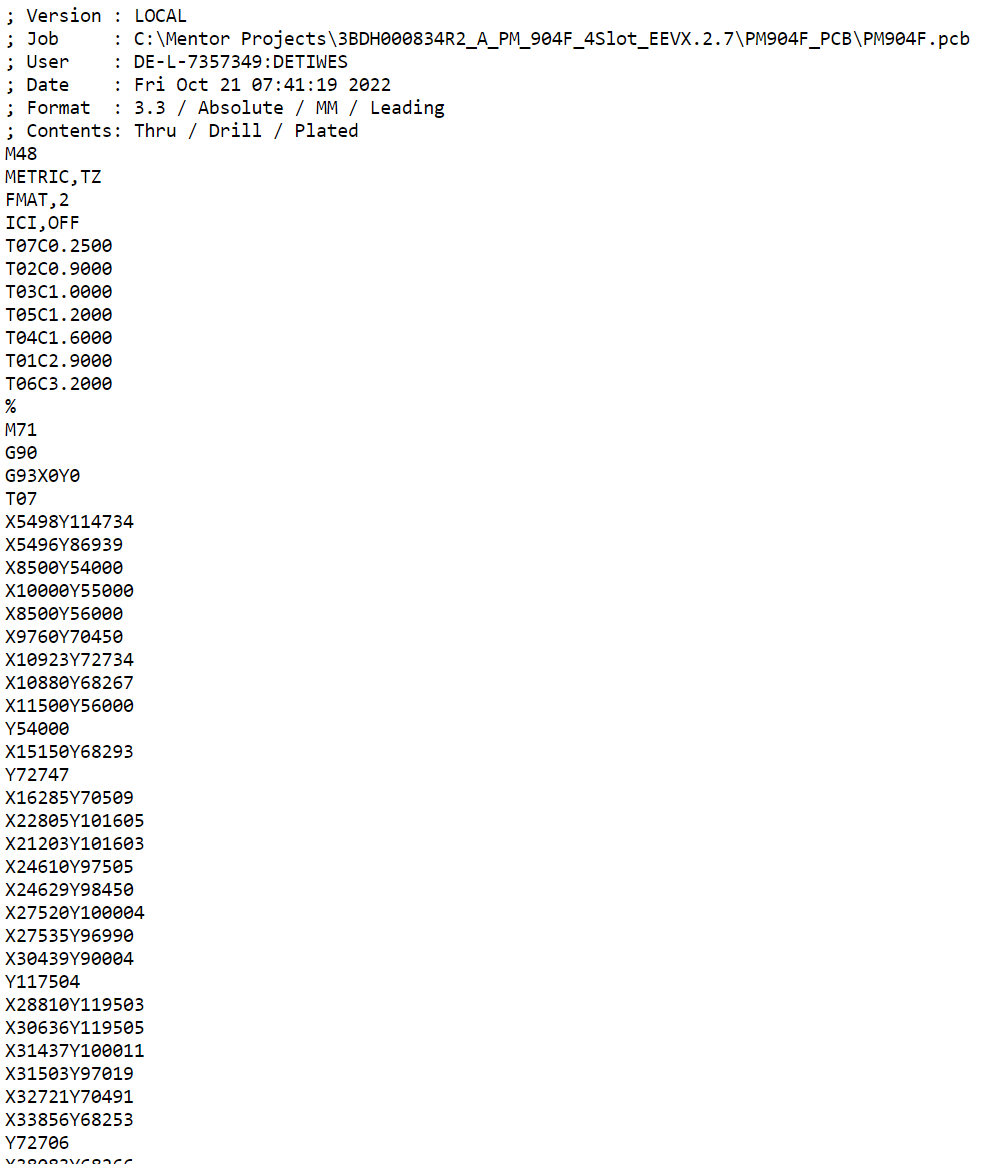

| Hardware design | All | NC Drill (part of gerber) | Standardized exchange format to PCB manufacturers to describe the required holes. Each type of hole (plated or non-plated holes, buried vias, blind vias/microvias) requires a separate file. The files in general are ASCII files that list the drill sizes and drilling coordinates per size. Imported to manufacturing machines at PCB manufacturers. | NCD, … (file extension not fixed) | DMS | - |  |

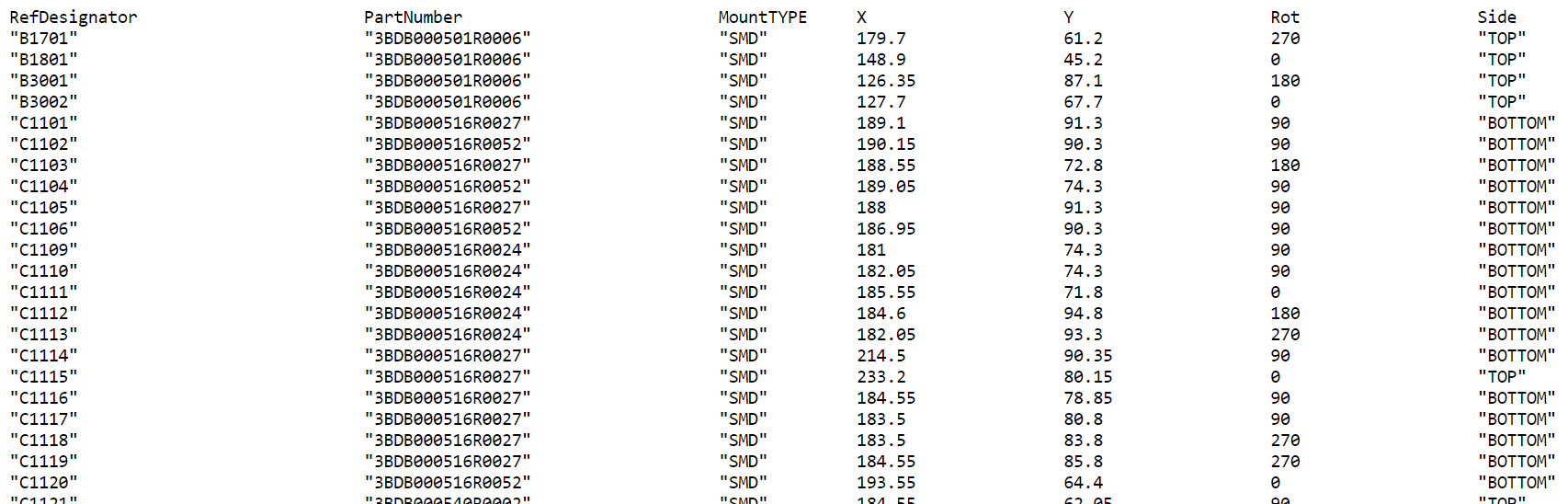

| Hardware design | All | Pick & Place files, also called CAM files | Exchange format to EMS supplier for component mounting. ASCII file which includes mounting side, rotation, and coordinates for each component. | CAM, TXT, … (file extension not fixed) | DMS | - |  |

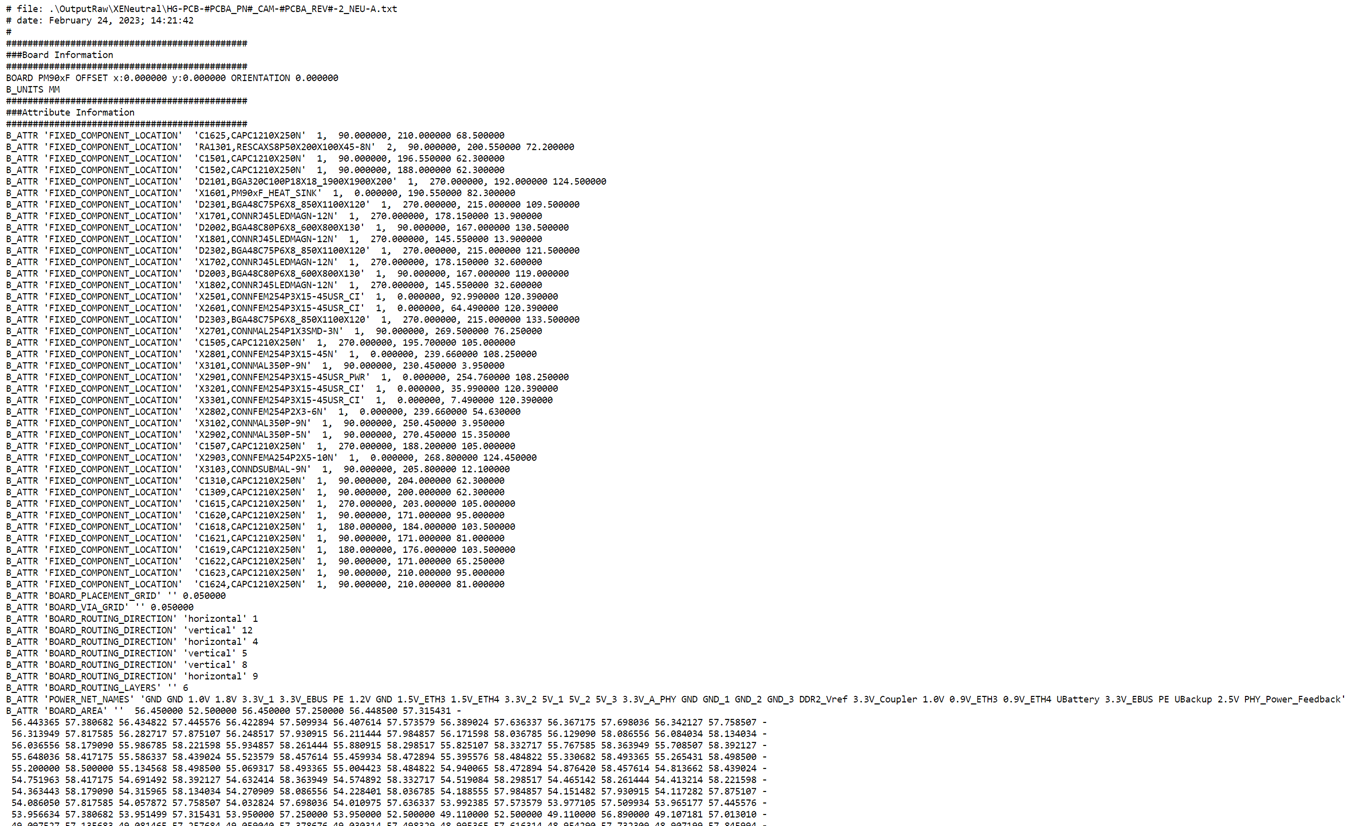

| Hardware design | Avnet | Neutralfile | Specific export format of the complete PCB layout and netlist in an ASCII file. This export format is exclusive to Siemens/Mentor Graphics. Used at Avnet Embedded (MSC) for preparation of ICT tests. | .neu or .txt | AOD | - |  |

| Hardware design | All | Net list | A "netlist" describes the connectivity of an electronic design | .ipc | DMS | - | - |

| Hardware design | Avnet | CCZ file | Netlist export format, binary file. Used at Avnet Embedded (MSC) for preparation of manufacturing end test, especially in case of Boundary Scan. The high-speed signal simulation tool Siemens HyperLynx can use this format as input to perform signal integrity simulations based on the actual layout. | .cce or .ccz | AOD | - | |

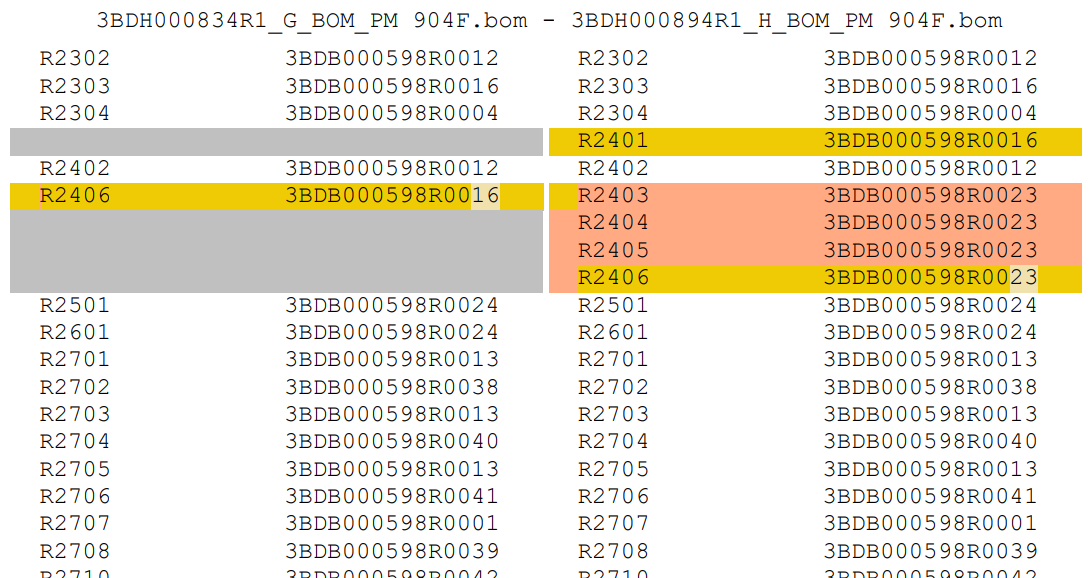

| Hardware design | Avnet | DIFF file | BOM comparison between current and previous product revision to highlight the differences to the EMS supplier. Generated based on interim BOM file from AOD. | AOD | - |  | |

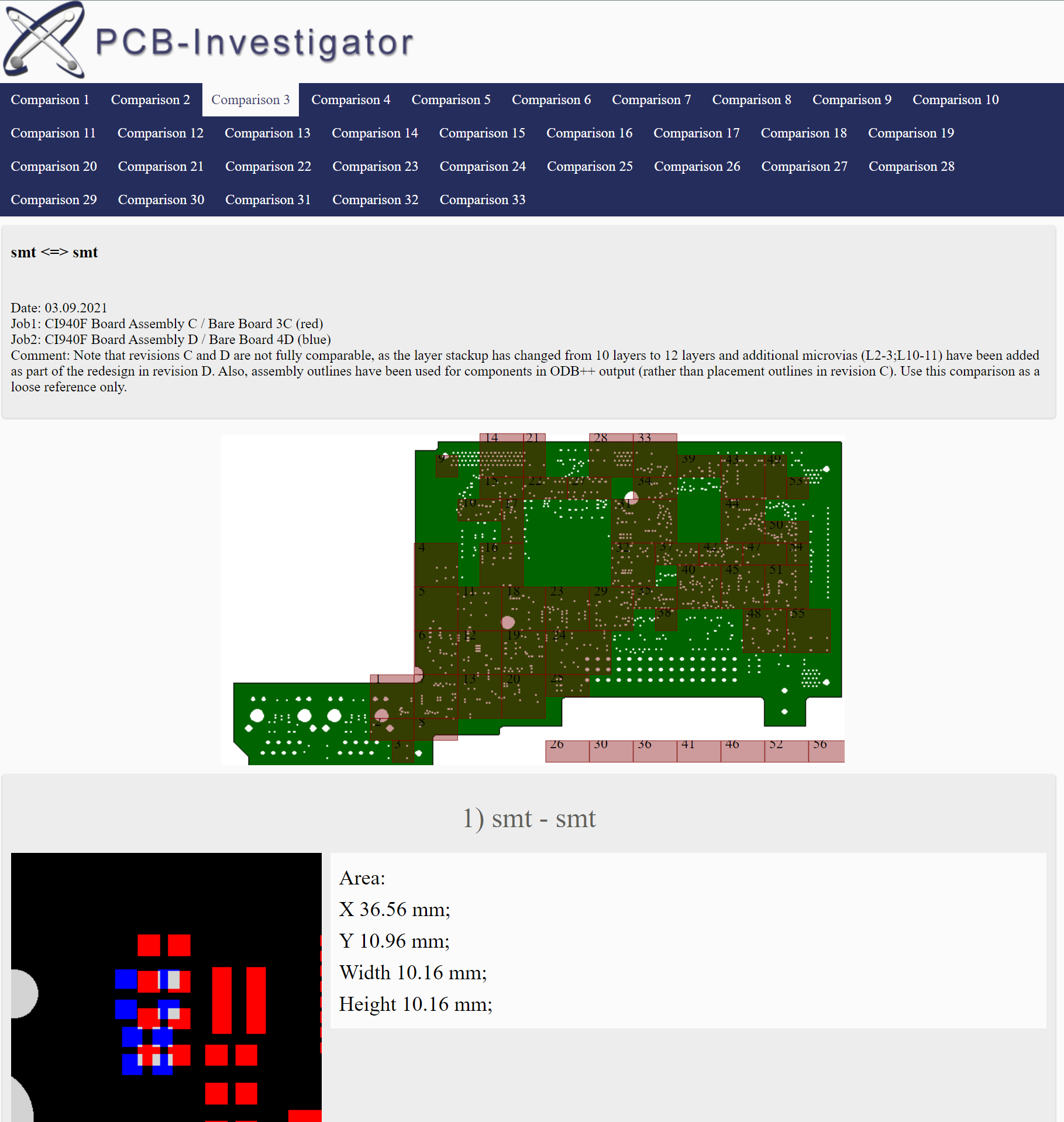

| Hardware design | Avnet | Layout diff | Layout comparison between current and previous product revision to highlight differences to the EMS supplier. Generated based on ODB++ data of both versions using the PCB Investigator tool. The tool compares each layer and generates a report highlighting every copper change. | .html | AOD | - |  |

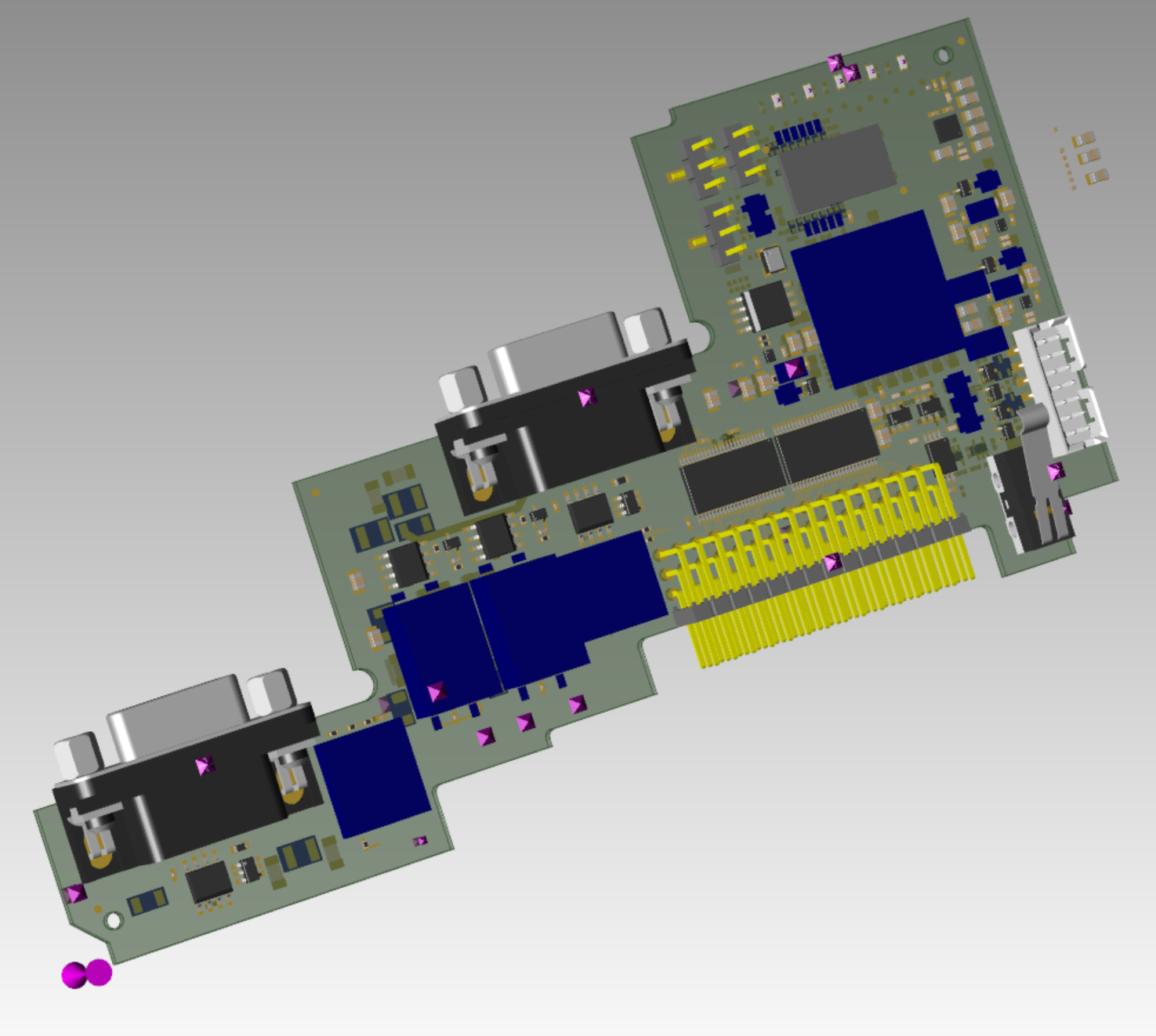

| Hardware design | Avnet | 3D data | Export of the PCB layout with 3D models of all components. Used by the mechanical team as input for final assembly drawing (how to mount the PCBA into the housing). Just started to also provide this as well to the EMS supplier Avnet Embedded (MSC). It is very helpful for them during ICT nail-bed adapter construction. | .step | AOD | - |  |

| Software | All | Firmware package | Hardware dependant software. The firmware is added as components into the parts list. This also contains a firmware test file that is deleted after production. | .bin or .hex | Visual studio | According to software process | - |

| Production test | All | Production test requirements (PTR) | ABB requirement on manufacturing test. Both hardware and software tests required | .docx | DMS | According to RACI | - |

| Other | All | Coating specification (PCBA) | General coating specification Instruction for conformal coated printed circuit board assemblies (PCBA). There is also a coating specification in the arrangement drawings for each product. | DMS | Process document | - |

Review

The production package needs to be reviewed before sending to EMS.

The review process will follow PCP R&D Processes RACI (3BSE039313_en_TPF Names on RACI), and review record will be stored in DMS while the product document stored in Windchill. The change history and revision will be tracked in Windchill ch3.24.2 and ch3.6 in 7PAA016756F0012_en Windchill R&D user manual (800xA, Freelance, Melody, RLM02).

Baseline of product

- Configuration Management is responsible to input and confirm the versioning of firmware and software into Windchill described in ch7.1.4.3 of 7PAA016756F0012_en Windchill R&D user manual (800xA, Freelance, Melody, RLM02).

- The baseline of the product, including firmware and software, will be triggered via creating a new product revision in Windchill. After the product is approved, a baseline can be created via ' add new baseline' function described in ch7.1.5 & ch7.1.6 of 7PAA016756F0012_en Windchill R&D user manual (800xA, Freelance, Melody, RLM02).

- Only the latest approved revision of the hardware Artifacts will be migrated to Windchill and withdrawn on DMS.

Package delivery during development

To be decided. Currently, used ways are through Jira and emails.

Package delivery for the production start

- For GPV: through the GPV collaboration portal.

- For Avnet: through AOD or a file share on SharePoint.

For other EMS please contact your manager or release owner.