New Product Introduction (NPI)

Hardware products are manufactured by Electronic Manufacturing Services (EMS). The EMS is responsible for assembling the product according to ABB design. This page describes key items in the New Product Introduction (NPI).

Collaboration is key

Hardware products are assembled with a large number of individual components and designs. Hardware engineers have a tight collaboration with suppliers and manufacturers when developing products. Within ABB several functions are crucial to get our products into the market.

The purpose of this page is to give an overview of which collaborations are important to remember internally within ABB. This page is a complementary page for hardware development however the base is still found on the site regarding Integrated Project Management and Release process.

If you are shipping something to another country please contact our trade compliance officer. Also please see Trade Compliance.

Terminology used in product development

Evaluation board

Early-stage hardware is used for testing a part of a function or a design idea.

Mock-up

Early stage mechanics design. This is the first physical product of the mechanic's design. 3D printing is common at this stage.

Prototype

A suggested hardware solution that implements all the needed functionality.

Sample

An item that comes from the tools that will be used in production when producing mechanical items.

What is the difference between pilot, pre-series and 0-series?

These are all the same, however, different functions use different terminology. It is the first small batch of products (hardware, mechanics and firmware as intended to deliver to customer) coming from the production line. From this batch, a golden sample is used to conduct a product approval before serial production can start.

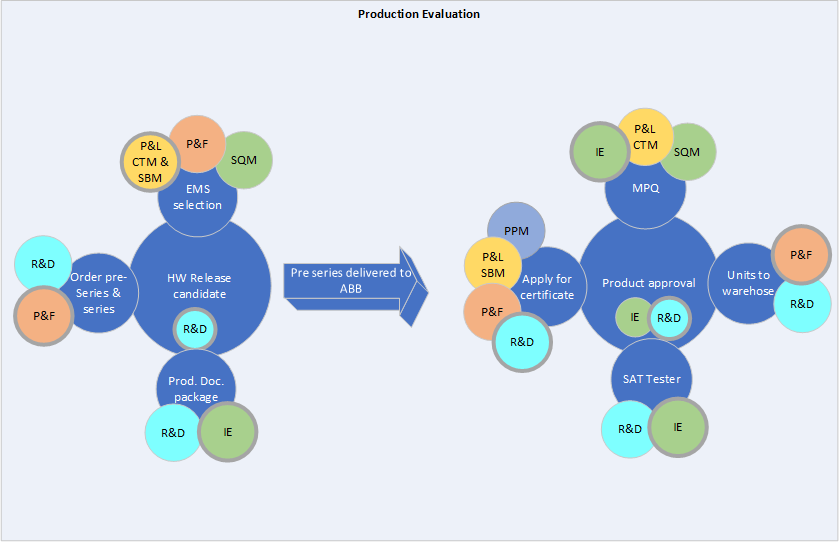

Legend to image

This is an instruction on how to interpret the below images. The main deliverable is in the middle of the circle diagram and associated items are overlapped between functions to indicate collaboration (start in the middle and move out to understand the order).

| Icon | Description |

|---|---|

| Functions | |

| Research & Development Designs products.Release owner are appointed within R&D to have the overall responsibility for NPI project. | |

| Planning & Fulfillment Makes purchases. Is responsible for ensuring series production. Planning orders and prioritizing them in production. This includes placing orders in good time at manufacturers enabling them to get the components in good time for delivery. Sometimes the production of prototypes interferes with the production series production therefore they are involved in prioritizing this as well. | |

| Procurement & Logistics: Supply Base Manager Ensures that ABB works with supplier that fulfill ABB requirements on suppliers | |

| Procurement & Logistics: Component Manager Monitors component availability, lifecycle, price etc. | |

| Procurement & Logistics: Category Manager Monitors the EMS checking on time delivery etc. | |

| Operations Quality: Industrial Engineering Ensures manufacturability. Ensures manufacturability and is the owner of bespoke ABB tools. Monitors First Pass Yield (FPY) in production and plans for tool maintenance. Involved in design ensuring manufacturability. | |

| Operations Quality: Supplier Quality Management Responsible for quality in production. Conducts audits at EMS. | |

| Operations Quality: Level 3 support Third level of support to customer. | |

| Product and Portfolio Management Responsible for the products, monitoring the market and giving requirements to R&D. | |

| Other | |

| Deliverable: an item that needs agreement across functions. | |

| Overlap: agreement between functions for a given deliverable. | |

| Bold outline: indicates responsibility. | |

| Light blue box: indicates a stage in development. | |

| Arrow: delivery to ABB from supplier or manufacturer. |

Legend to table

If the icon is in bold in the image. Then it is represented in the table with the bold font on the word Responsible. The function which has this bold font is responsible for driving the deliverable.

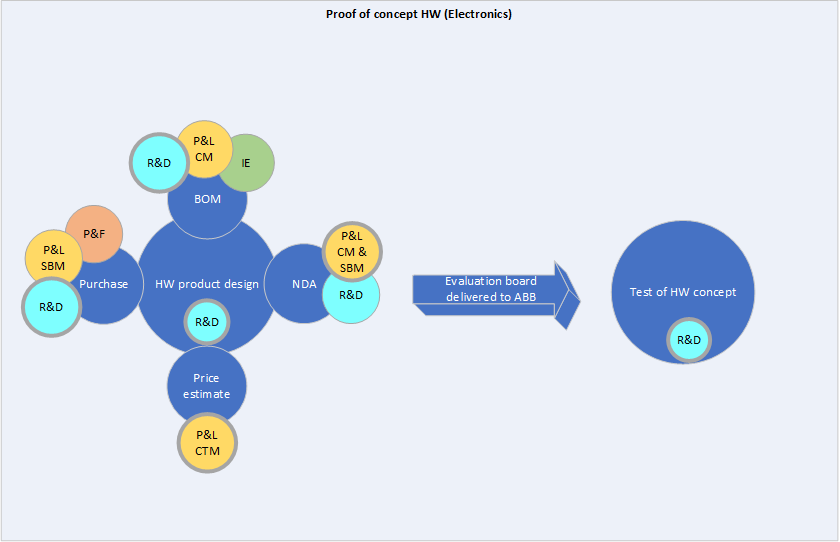

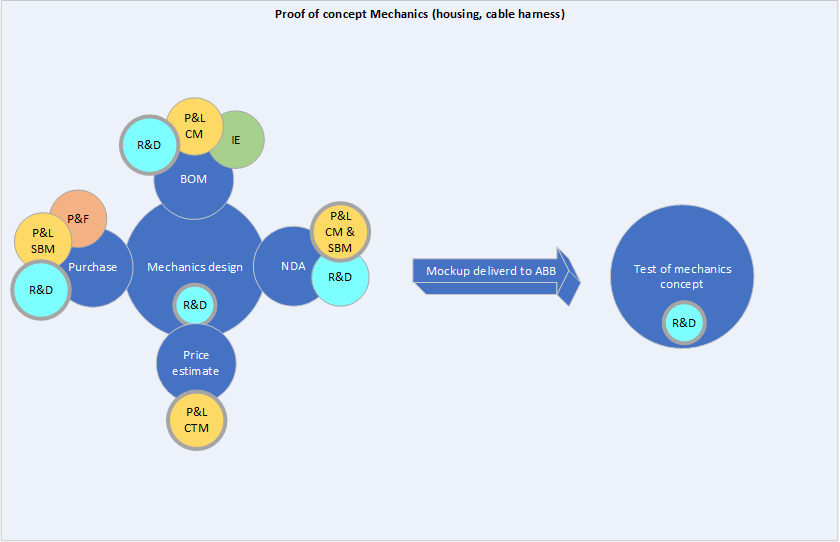

First stage: proof of concept

This is very early-stage development. Development requires quick turnaround time and designs are continuously getting more complex. In hardware, work is being done with rapid prototypes (evaluation boards) that test a certain function or requirement. An evaluation board can check certain components or the complete design depending on the maturity of the development. For mechanics, mockups are used to verify early designs. Usually, mockups are 3D printed in order to evaluate the design with a quick turnaround time.

Proof of concept hardware

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE |

|---|---|---|---|---|---|---|

| HW product design | Responsible for desinging the product | |||||

| Purchase | Responsible for ensuring that supplier is approved by P&L SBM and P&F before the purchase order is released. This is true for anything that is purchased (solder, PCB, oscilloscope etc). | Approves the selected supplier (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | |||

| Price estimate | Responsible for creating a rough estimate of the final product including production costs. | |||||

| NDA (Non-Disclosure Agreement) | Ensures that an NDA is in place before starting the collaboration with the manufacturer. Use the P&L team for assistance. | Approves the selected supplier (8-10 weeks). | Responsible for supporting R&D when an NDA needs to be set up. | |||

| BOM (Bill of material) | Responsible for creating the BOM and for its contents. | Are required to give input on the component choices and make suggestions regarding lifecycle, availability, material compliance etc. | Required to give input to the BOM in regards to DFX. | |||

| Test of HW concept | Responsible for testing the proof of concept. |

Proof of concept mechanics

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE |

|---|---|---|---|---|---|---|

| Mechancis design | Responsible for desinging the product | |||||

| Purchase | Responsible for ensuring that supplier is approved by P&L SBM and P&F before the purchase order is released. This is true for anything that is purchased (solder, PCB, oscilloscope etc). | Approves the selected supplier (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | |||

| Price estimate | Responsible for creating a rough estimate of the final product including production costs. | |||||

| NDA (Non-Disclosure Agreement) | Ensures that an NDA is in place before starting the collaboration with the manufacturer. Use the P&L team for assistance. | Approves the selected supplier (8-10 weeks). | Responsible for supporting R&D when an NDA needs to be set up. | |||

| BOM (Bill of material) | Responsible for creating the BOM and for its contents. | Are required to give input on the component choices and make suggestions regarding lifecycle, availability, material compliance etc. | Required to give input to the BOM in regards to DFX. | |||

| Test of Mechanics concept | Responsible for testing the proof of concept. |

Design accepted

When it has been decided that the concept is good enough to proceed with, G2 can be passed.

: There are more things needed to pass G2 please seeIntegrated Project Management

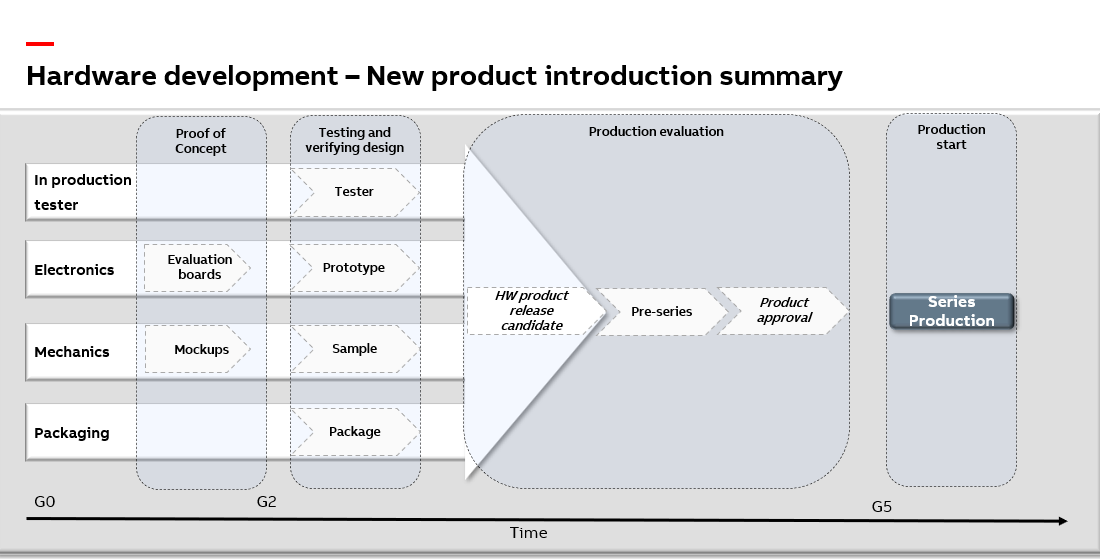

Second stage: testing and verifying the design

In this stage of development, the product is tested with regards to hardware, firmware, and mechanics as well as preparing for production.

- Ordering of testers is done when the hardware is judged to be close to the final product. After the testers have been ordered only minor adjustments can be made. Testers are individual for each EMS.

- Prototypes are in comparison to the evaluation boards complete in terms of functionality, we have the correct BOM, PCB and material in the mechanical samples.

- Samples are used to verify that the tools for mechanics have been produced according to the design. As the tools for mechanics are bespoke these also have a lead time of 16 weeks and only minor adjustments to tolerances can be made after ordering the tool.

- Packaging is designed by an external partner. The role of R&D is to design the product and the external packaging partner designs the package(box) in which the product will be placed and delivered to customers.

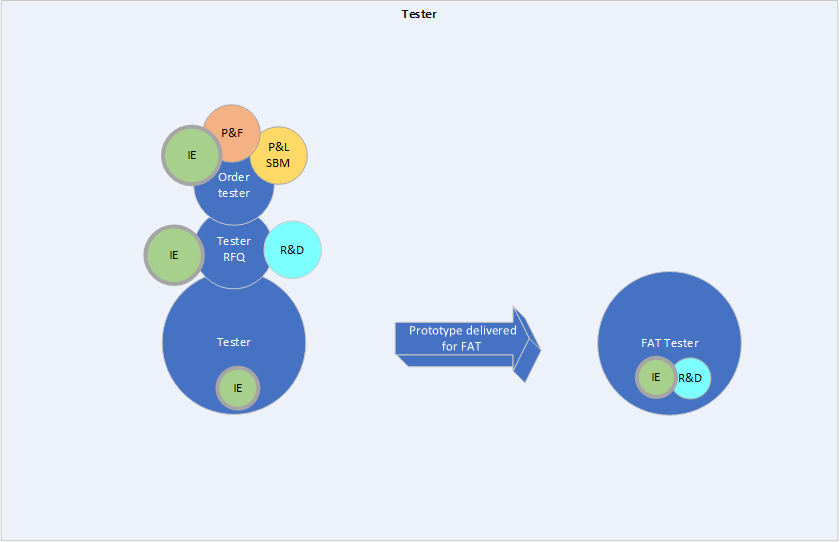

Tester

A precondition for initiating the work regarding testers is the PTR (production test requirements).

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE |

|---|---|---|---|---|---|---|

| Tester | Responsible for tester | |||||

| Tester RFQ (Request For Quotation) | Review quotation. | Responsible for requesting quotations. | ||||

| Order tester | Approves the selected supplier (8-10 weeks). | Releases purchase order. | Responsible for ensuring that the supplier is approved by P&L SBM. Tester usually has about 16 weeks lead time. | |||

| FAT (Factory Acceptance Test) Tester | Involved if requested. | Responsible for accepting the FAT. |

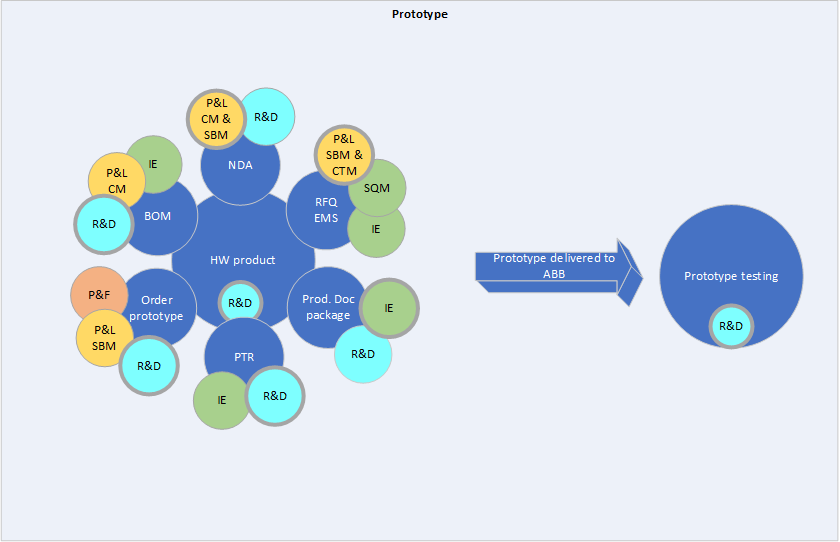

Prototype

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE | SQM |

|---|---|---|---|---|---|---|---|

| HW product | Responsible for the product design. | ||||||

| Order prototype | Responsible for ensuring that supplier intended to order prototypes from is approved by P&L SBM. | Approves the selected supplier (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | ||||

| PTR (Production Test Requirements) | Responsible for writing the PTR. | Ensure that the PTR covers what is needed from a manufacturing view. | |||||

| Prod. Doc Package (Production documentation package) | Ensure that all documentation is present that is needed please view the production package. | Responsible for checking that the production documentation is correct and distributed to relevant EMS. | |||||

| RFQ (Request for quotation) EMS | Responsible for approving the selected manufacturer (8-10 weeks). | Responsible for choosing the manufacturer. | Give input regarding experience with the manufacturer. | Give input on the quality that the selected EMS delivers. | |||

| NDA (Non-Disclosure Agreement) | Ensures that an NDA is in place before starting a collaboration with the manufacturer. Use the P&L team for assistance. | Approves the selected supplier (8-10 weeks). | Responsible for supporting R&D when an NDA needs to be set up. | ||||

| BOM (Bill of material) | Responsible for creating or updating the BOM if needed. | Are required to give input on the component choices and make suggestions regarding lifecycle, availability, material compliance etc. | Required to give input to the BOM in regards to DFX. | ||||

| Prototype testing | Responsible for testing of the product |

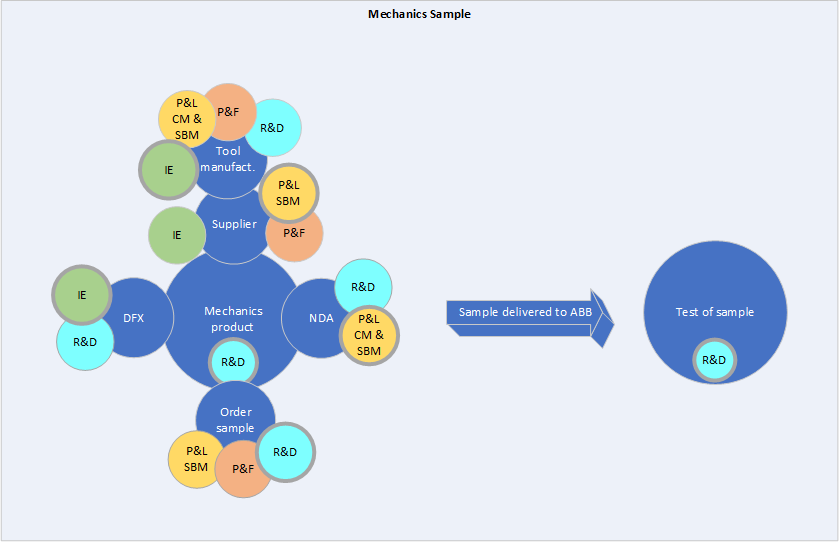

Mechanics sample

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE |

|---|---|---|---|---|---|---|

| Mechanics product | Responsible for the mechanics product design. | |||||

| DFX (Design for X) | Prepare design and distribute design to relevant parties. | Responsible for the design in regards to DFX. | ||||

| Order Sample | Responsible for ensuring that supplier intended to order samples from is approved by P&L SBM and P&F to release the purchase order. | Approves the selected supplier (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | |||

| NDA (Non-Disclosure Agreement) | Ensures that an NDA is in place before starting a collaboration with the manufacturer. Use the P&L team for assistance. | Approves the selected supplier (8-10 weeks). | Responsible for supporting R&D when an NDA needs to be set up. | |||

| Supplier | Responsible for approving the selected manufacturer (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | Give input on which tool manufacturer to choose. | |||

| Tool manufacturer | Include in the decision. | Approves the selected tool manufacturer (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | Responsible for final choice and quotations through the supplier. | ||

| Test of sample | Responsible for approving and testing the product. |

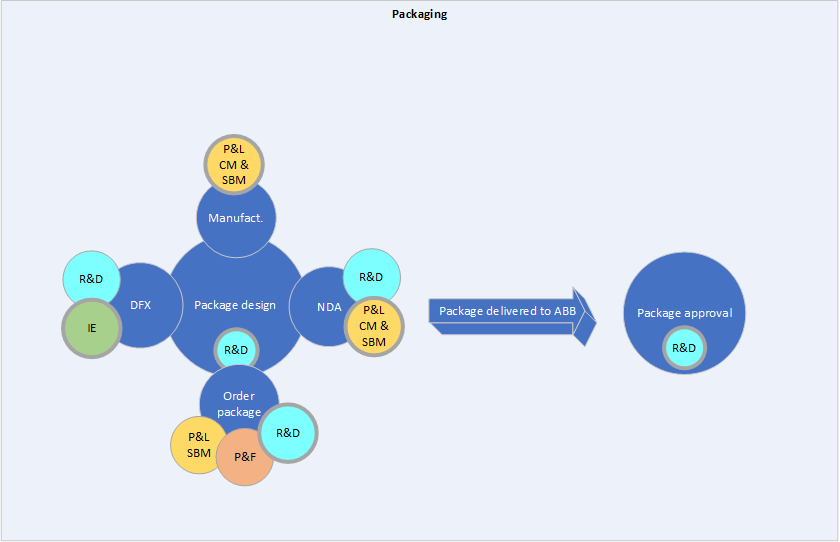

Packaging

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE |

|---|---|---|---|---|---|---|

| Package design | Responsible for the product design that is then given to the manufacturer that will then create the design for the packaging. | |||||

| Order package | Responsible for ensuring that the supplier intended to order samples from is approved by P&L SBM and P&F to release the purchase order. | Approves the selected supplier (8-10 weeks). | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | |||

| NDA (Non-Disclosure Agreement) | Ensures that an NDA is in place before starting a collaboration with the manufacturer. Use the P&L team for assistance. | Approves the selected supplier (8-10 weeks). | Responsible for supporting R&D when an NDA needs to be set up. | |||

| Manufacturer | Responsible for approving the selected manufacturer (8-10 weeks). | Selects the manufacturer. | ||||

| DFX (Design for X) | Prepare the design of the product that will be in the package. | Responsible for ensuring that the package is manufacturable. | ||||

| Package approval | Responsible for ensuring that the packaging fits the product and complies with ABB branding. |

Tests and verification passed

When testers, hardware, mechanics and packaging are tested and verified the production evaluation can start.

Third stage: production evaluation

Production is evaluated with the use of a pre-series (can also be called a 0-series). Samples from this series are used to conduct the product approval (golden sample) and each manufacturer is also qualifying their production process.

Hardware release candidate

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE | SQM |

|---|---|---|---|---|---|---|---|

| HW release candidate | Responsible for ensureing that the design is ready for pre-series and product approval | ||||||

| Order pre-series & Series | Ensure that the design is ready to make a purchase in preparation for pre-series and series production. | Responsible for releasing the purchase order. | |||||

| Prod. Doc package (Production documents package) | Creates the production documents package please see Production package. | Responsible for checking that the production documentation is correct and distributed to relevant EMS. | |||||

| EMS selection | Responsible for approving the selected manufacturer (8-10 weeks) | Give input regarding which manufacturer is a good choice. | Releases purchase order. | Gives input regarding the quality that the EMS delivers. |

Product approval

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE | SQM | PPM |

|---|---|---|---|---|---|---|---|---|

| Product approval | Responsible for the product approval | Finalize setup at EMS. | ||||||

| Apply for certificates | Responsible for ensuring that all required data is available. Please see guide regarding How to handle certifications | Approves the selected notified body (8-10 weeks) | Purchase Orders are created by P&F in SAP, however, this can be delegated to assistants. | Inform PPM according to How to handle certifications. | ||||

| SAT (Site Acceptance Test) tester | Support when needed. | Responsible for ensuring that the SAT has passed. | ||||||

| Units to warehouse | Inform P&F to add units to stock. | Responsible for ordering and adding to stock a sufficient number of units. | ||||||

| MPQ (Manufacturing Process Qualification) | Give input to the MPQ when needed. | Responsible for ensuring that the MPQ is filled in by the manufacturer | Ensure that the items needed for audits are covered in the MPQ document. This is used when auditing the manufacturer |

Production evaluation passed

Milestone checklists for G5 have been finished and all work has been finalized then the product is ready to go to series production.

- At this stage, ABB is ready to release.

- Products are on stock ready to be delivered to customers.

- Production has been approved.

: There are more things needed to pass G5 please seeIntegrated Project Management

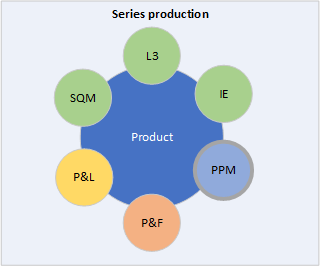

Fourth stage: production start

After G5 has been passed and R&D is done with development. Responsibility after this stage is split between several functions. The product is produced in series and is delivered to customers.

Series production

| Item | R&D | P&L SBM | P&L CTM | P&L CM | P&F | IE | SQM | PPM | L3 |

|---|---|---|---|---|---|---|---|---|---|

| Product | Supports when needed | N/A | Follows up the manufacturers with on-time-deliveries, communication etc. | Monitors component availability etc | Handles orders and deliveries to customers | Monitors the quality from our manufacturers. Conducts audits and handles field returns. | Monitors the quality from our manufacturers. Conducts audits and handles field returns. | Responsible for the product. Monitors the market trends and decides on redesigns or additions to the product portfolio when needed. | Level 3 maintenance handles support cases from customer. When they cannot solve it the case comes to R&D |

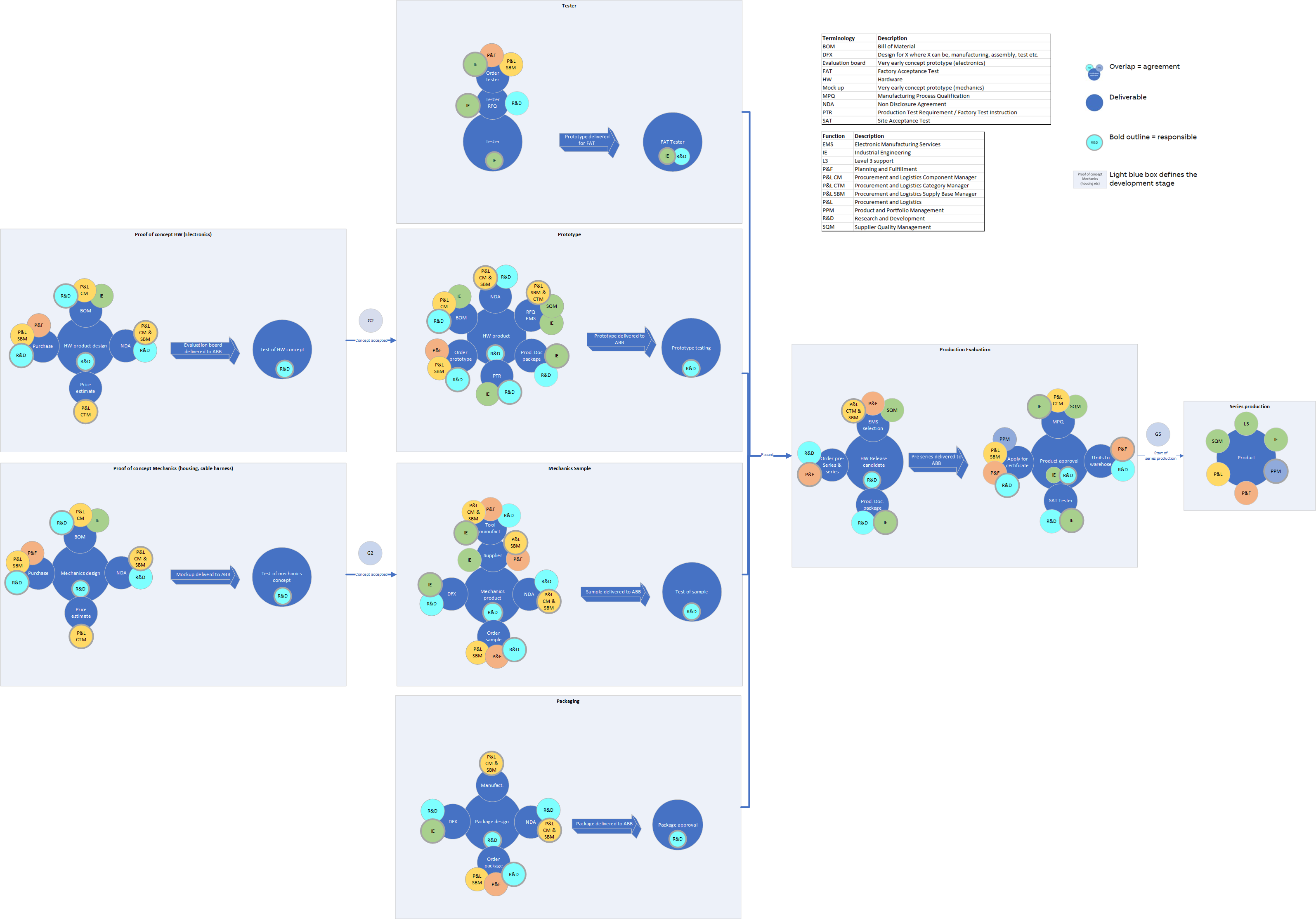

NPI process overview

Everywhere where P&L SBM is present in the image below it means that the suppliers need to be qualified. It is a good idea to check this as soon as a supplier is being considered as it takes about 10 weeks to approve a new supplier. If there is no need to qualify a new supplier, then there is no contact P&L SBM. This is true for any purchase to ABB.