How-to Manage Stop and Start Orders

This guide describes the routines for stopping and restarting the manufacturing, delivery and/or ordering of products within PCP.

For further information regarding communication when stopping and restarting manufacturing and delivery, see 3BSE086007 Field Communication overview

Intended for

- Product owners, product managers, and quality control managers.

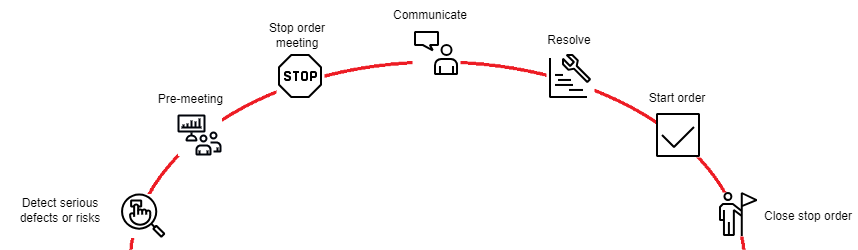

Activities

Detect serious defect or risk

A serious issue concerning a product is detected, and it is considered so serious that the units must be prevented from being delivered immediately. If there is a risk of considerable capital loss by continuing to manufacture the unit, even manufacturing must be stopped.

The issue may be triggered by e.g. R&D, a supplier, component shortages, customer issues, or a certification body. No matter which, the product owner is responsible for handling the issue.

Pre-meeting

- The product owner calls the product manager to a pre-meeting.

- The product owner drafts a Jira case capturing general information about the issue and saves the draft in Jira.

Stop order meeting

The product owner calls representatives from Product Management, Planning and Fulfillment (P&F), Procurement and Logistics (P&L), and Quality & KPIs to a cross-organizational stop order meeting. Heads of Operations, Portfolio and Product Management (PPM) and R&D should be invited and can choose to participate or delegate.

The meeting follows this standard agenda:

- Presentation of the draft Jira case, prepared by the product owner.

- Discussion about inventory: reviewing how many pieces PCP has in stock.

- Based on feedback and previous points, reaching a full agreement to stop and officially halt operations within the organization.

- If the decision is to stop, the product owner should immediately change the status from “Drafting” to “Active Stop Order” in the Jira case.

- In the event of a “Stop of Production”, PCP must immediately inform manufacturers (EMS), see next paragraph. The product owner should activate the corresponding child case, assigning the email contact(s) of affected manufacturer(s). For a “Stop of Delivery”, no actions are required regarding manufacturers, as the information is internal and can easily be tracked in Jira.

Communicate

When the product owner changes the Jira case status to “Active Stop Order”, an internal (PCP) email is sent automatically from Jira to all members of the shared inbox (SE_PA_XA_D_Stop_delivery), who then takes appropriate actions.

In the case of “Stop of Production”, an email must immediately be sent to inform relevant manufacturers to halt the manufacturing process, see Mailing list for contacts and addresses. In addition, the manufacturer(s) receives an automatic email, linking to the specific child case for the supplier.

Inform product management within the Division about the issuance of a stop order.

Resolve

When the stop order has been activated, R&D investigates the issue. The investigation is completed when the root cause of the issue is resolved, which also is the starting point for the start order.

Start order

- The product owner and product manager agree on restarting.

- The product owner changes the Jira case status from “Active Stop Order” to “Restart Order”. In case of “Start of Production”, the product owner activates the supplier’s child case and informs the EMS via email, see Mailing list for contacts and addresses. In both cases Jira generates an automatic email notifying internal and external parties and linking to the corresponding Jira case.

- Only if needed. R&D may required additional internal or external rework.

Close the stop order

When no further actions are needed, the product owner closes the stop order, by changing the Jira case status from “Restart Order” to “Stop Order Closed”.

Details

Tools

| Tool | Reference/Useful links |

|---|---|

| Jira | Stop and Start Order Status - ABB |

| Jira dashboards | ABB: Stop and Start Order Status - ABB Suppliers: Stop and Start Order Status -Suppliers - ABB |

| PowerBI | PCP Stop and Start Order Dashboard - Power BI |

| Process description | 7PAA016700 Start Stop Order Process and Instructions |

| eLearning | ABB MyLearning |

| Shared mailing list | !SE_PA_XA_D_Stop_delivery |

Mailing list

| Manufacturer | Email address |

|---|---|

| AQ Plast | Wisam Dibes |

| AQ Plastronic | Yoana Nikolova |

| AQ Wiring | Malgorzata Zgirska |

| GPV | Starstop GPV |

| Kitron | Paulina Kilnaite |

| ML&S (Duotec) | Anja Meyer abb-start-stopp@mlands.com |

| Scanfil | Piotr Pol |

| Scanfil Suzhou | Lily Hao Vicent Li |

| Seifert Systems | Jonathan Muscat |

| TE Connectivity | Silvia Tobajascuevas jzisch@te.com |