Calibration of PAPCP REH Hardware Equipment

This guide describes the procedure for monitoring, inspection and calibration of used test and measurement equipment. It is valid for the PAPCP REH instruments.

Intended for

Hardware engineers working in the PAPCP R&D HW lab (Tidö) in Västerås Sweden, and Minden Germany.

Instrument register

R&D HW lab, location Minden (Germany):

A starting point for the calibration activities is 2PAA116673_PCP_RDCH_Minden_Instrument_Calibration.xls Instruments Register, stored on department hard-drive G:\Hardware\Projekte\Prüfmittelüberwachung.

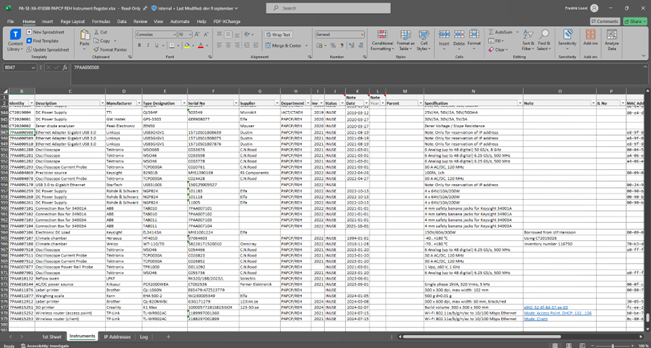

A starting point for the calibration activities is the PA-SE-XA-018386, PAPCP REH Instrument Register stored in OnePCP DMS. This register is a document where all instruments used in the PAPCP HW lab are listed.

The following are the most important columns of the instrument list document:

- Identity: Each instrument shall have a unique identity number from the 7PAA series. Typically reserved from the ABB number generator, e.g. 7PAA001281.

- Description: A short description of what kind of instrument, e.g. Oscilloscope.

- Manufacturer: The manufacturer of the instrument, e.g. Tektronix.

- Type designation: The model of the instrument, e.g. MSO46.

- Serial number: Serial number of the instrument, e.g. C033598.

- Supplier: Supplier of the instrument, e.g. C.N.Rood.

- Status: The status of the instrument shall be noted, e.g. in use, scrapped, etc.

- Date: The year the instrument is purchased, e.g. 2021-03-01.

- MAC Address: The LAN MAC address of the instrument shall be noted, e.g. a4-06-e9-e9-6f-60

- Note Cal.: It shall be noted if the instrument shall be included in possible calibration, e.g. yes or no.

- Cal. Protocol: A reference to calibration protocol shall be noted.

- Note Cal. Date: The calibration date shall be noted, e.g. 2024-06-26.

- Note Int.: The calibration interval shall be noted in months, e.g. 12.

- Note Cal. Due Date: The due date is automatically calculated using the “Note Cal. Date” and “Note Int.” columns.

- Note IP Address: Each instrument with an IP port shall have a unique IP Address, and shall be reserved from the “IP Addresses” tab in this document.

Keeping the equipment inspected and calibrated

Responsible

One nominated person – from e.g. test and certification team – is the coordinator for keeping the equipment inspected and calibrated.

The responsible person shall check the instrument list regularly for upcoming calibration jobs and initiate the calibration workflow (normally, ask for offer → place order → ship and receive the parcel). The calibration itself is accomplished at the following places:

- Directly at the manufacturer (e.g. Tektronix).

- 3rd-party service partners (e.g. Intertek).

Marking of instruments

The instruments that are noted with “no” in the “Note Cal.” column shall be marked with a visible label that states that they are not intended to be calibrated.

The instruments that are noted with “yes” in the “Note Cal.” column shall at least have one of each specific instrument variant with valid calibration. To calibrate more of the same instrument variant will be considered from time-to-time and the need for additional instruments, for example before formal tests. Therefore, since it can exist instruments where the valid calibration has expired, it is the responsibility of each developer that will use that kind of instrument to make sure they use an instrument with a valid calibration. If there is a need for additional calibrations, it shall be addressed to the responsible person (calibration coordinator) listed above.

Calibration intervals, labels, and certificates

The calibration interval is normally 1 year, driven by the ISO 9000 standard. A 1-year interval is also recommended by most manufacturers.

After the instrument has been calibrated it gets a visible label with the calibration date and a calibration certificate is generated from the company that performed the calibration.

The calibration certificate shall be named with its ID, manufacturer, and model, e.g. “7PAA001281 Tektronix MSO46” and be stored in the Calibration Protocol folder in One PCP DMS.

Evaluation and follow-up

The calibration coordinator evaluates the details in the calibration report, especially in terms of deviations in the function or parameters of that equipment. In case the tolerance deviations are too high a special precaution takes place: check of persons who have used that equipment since the last valid calibration and who could have been made faulty measurements meanwhile. Each developer must judge the impact of his last tests: if it's critical or without any influence. If critical, and as a consequence, all relevant measurements must be repeated.

After briefing ABB about deviations/failures in the equipment, the calibration partner in-time normally offers a repairment/adjustment of the instrument.