How-to Perform Supplier Ex Audits

This guide describes the activities to perform explosion protection (Ex) audits at external manufacturing services (EMS).

It also includes additional information such as the reason and time intervals for external Ex audits under Details.

Intended for

Ex representatives and Ex component responsibles.

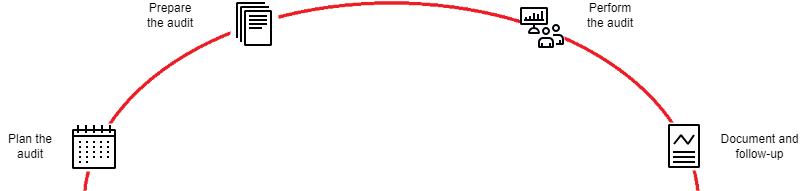

Activities

Plan the audit

The Ex audit is mandatory for EMS that provide Ex-certified products or services. The appropriate EMS are tagged in Jira as "Ex relevant" and have an appointed “Ex Authorized Person”.

The Ex audit should be carried out in collaboration with the Supply Quality Management (SQM) team. The SQM team uses the tool Supplier Audits in Jira to plan and set the audit date. The supplier audit plan keeps track of and organizes audits.

The SQM team invites the Ex team to audit Ex-relevant EMS to cover the specific explosion protection requirements.

Prepare the audit

The audit is based on a checklist, see 7PAA019494 Ex Supplier Audit Template. Adapt the sessions and the checklist to the respective functions and areas to be audited. If possible, include new focal points for recurring audit sessions.

The audit shall consider the Ex type of protection of the produced products. Guidance for the audit can be found in Annex A of ISO / IEC 80079-34, especially the following topics:

- A.3 Ex d – Flameproof enclosures covered by IEC 60079-1.

- A.4 Ex i – Intrinsic safety covered by IEC 60079-11.

- A.5 Ex e – Increased safety covered by IEC 60079-7.

- A.10 Ex n – Equipment covered by IEC 60079-15, Ex nA and Ex nC.

Perform the audit

Start by following up on the findings from the last audit to evaluate the organization’s ability to implement (mandatory) improvements.

Go through all questions in the checklist to address the specific requirements from ISO / IEC 80079-34 relevant to the audited EMS.

Finally, the participants should align and agree upon findings and observations.

Document and follow-up

The audit shall be documented in a report (the filled-in checklist), where the findings are initially documented and relevant information from all audit days is summarized.

The audit report shall be stored in Jira in accordance with 7PAA014999 Minimum Retention Record. The approval workflow can then be carried out with the Ex representative as approver.

All findings shall be documented and followed up in Jira together with SQM.

The EMS is responsible for planning and taking corrective actions to resolve any findings in an audit assigned to them. All reporting shall be done in Jira.

In addition to the findings, some positive observations can also be made. These findings can be shared with the EMS as examples of best practice.

Details

About Ex audits at EMS

The PCP organization is certified for developing and producing equipment for explosive atmospheres according to ISO / IEC 80079-34. This also requires an audit program covering externally provided products and services to ensure that the Ex-certified products conform to the certificate.

The audit examines all aspects of the externally provided service, considering the nature of the product and the nature of the external provider. This includes appropriate production and test processes and their records, production documentation and working instructions, incoming inspections, training of staff, handling and storage of material and products, and any other elements that can affect the compliance of the Ex product to the certification parameters.

The time period between two audits must not exceed 12 months.

In the case of a new EMS, the Ex audit is carried out in conjunction with the supplier production qualification process (SPQP) assessment, while in the case of a recurring audit, it takes place alongside the process audit qualification (PAQ).