How-to Handle Ex Non-conformities

This guide describes the measures and activities to handle non-conformities for equipment intended for explosive atmospheres.

The PCP organization is certified for development and production of equipment for explosive atmospheres according to ISO / IEC 80079-34. In addition to ISO9001 and local product safety laws, this standard requires adequate handling of deviations and the control of non-conforming outputs for equipment intended for explosive atmospheres.

Non-conformity in this context means deviations between the product delivered and the approved and certified design, including deviating components, wrong markings, incorrectly performed production, or incorrect or missing routine tests.

This guide addresses these requirements and describes the measures and actions to take.

Intended for

Members of the Explosion Protection team, Portfolio & Product Management (PPM), and Supply Quality Management (SQM).

Activities

Inputs

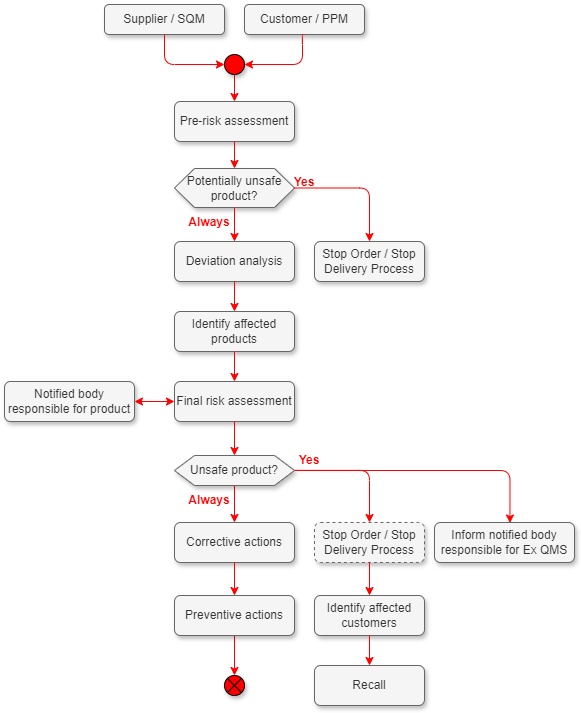

Information about deviations will be announced from production via SQM or from customers via PPM.

Deviations are managed via a Jira case or an Azure DevOps (ADO) epic/bug.

Pre-risk assessment

The Explosion Protection team performs a first immediate pre-risk assessment. Depending on the nature of the deviation, additional members of SQM and/or PPM can be involved. The assessment focuses on the affected product and its requirements from the explosion protection certification. If a potential risk is identified, actions shall be taken according to How-to Manage Stop and Start Orders.

Deviation

A report template is available for handling non-conformities of equipment intended for explosive atmospheres: 7PAA018860 Deviation Assessment IEC80079-34. This template gives guidance on performing all necessary actions. First, the deviation needs to be described in detail. This could include reports from Electronics Manufacturing Services (EMS), SQM, photos, references to Jira cases, and all other helpful information to understand the deviation.

Relevant Jira case numbers and ADO epic/bug numbers should be referred to.

For a better understanding of the deviation, the certified design can be shown for reference.

Affected products

All affected products and batches need to be collected. This includes investigating if the issue could affect other products due to:

- The same faulty production process is used on other products.

- The same faulty components are used in other products.

- The same faulty handling or communication process used for other products.

- Etc.

All related product certificates which may be impacted by the deviation need to be identified, e.g. ATEX, IECEx, UL, and CCC.

Risk assessment

Perform a risk assessment based on the identified deviation and the certification of the affected products. The assessment team should include, but is not limited to, relevant members from the Explosion Protection team, development engineers and supplier quality engineers.

The risk assessment should be based on the relevant types of protection and their relevant standards:

Explosion protection:

- EN/UL/IEC 60079-0

- EN/UL/IEC 60079-1

- EN/UL/IEC 60079-7

- EN/UL/IEC 60079-11

- EN/UL/IEC 60079-15

- ANSI ISA 12.12.01

- GB/T 3836.1-2021, GB/T 3836.3-2021, GB/T 3836.4-2021, GB/T 3836.8-2021

- etc.

Electrical safety:

- EN/UL/IEC 61010-1

- EN/UL/IEC 61010-2-201

- UL508

- etc.

Special focus should be on health, safety, and environmental impact due to the risk of explosion from sparks, high temperatures, or electrical shocks.

Appropriate to the degree of risk, it is highly recommended that the notified body responsible for the issue of the product certificate is included in the assessment. Additional tests may also be necessary for the risk evaluation, either at ABB or at notified bodies. These test results shall be documented or referred to in the report.

Decision

Once the risk assessment is done, it must be decided whether the deviation is a potential risk for health, safety, and/or environment.

The minimum relevant roles for the decision are:

- Ex representative and Ex component responsible.

- Head of hardware design.

- (Supplier) quality management

- Product owner or product manager

The decision must be argued and documented in the deviation assessment report.

If the result is a potential risk, actions shall be taken according to:

Corrective actions

Independent of decision, the deviation needs to be addressed immediately and then corrected in e.g. a minor hardware revision, temporary correction, or a new release. See the following for reference:

If the deviation is based on a faulty processes or handling at the supplier, SQM shall take care according 2PAA123951 Handling Supplier Issues .

If the deviation is based on unclear, missing, or faulty processes in R&D, the responsible process owner shall be informed, see Process Teams.

If the deviation is based on unclear, missing, or faulty processes outside of R&D, the responsible process owner shall be informed. Such issues can be handled in multiple ways, see the following references for examples:

- Supplier Audits

- Handle Field Returns, Warranty & Recall

- Handle of Field Recalls

- Manage Test Equipment Development

- Qualify Manufacturing Process at EMS

- Manage Components

Preventive actions

It is important to improve our products, designs, and processes to prevent possible deviations. Therefore, consider the items in the corrective actions above and also PCP’s continuous improvement program: Continuously Improve & Enable Change.