How-to Perform Ex Internal Audits

This guide describes the activities to perform explosion protection (Ex) audits within the PCP organization.

It also includes additional information such as the reason and time intervals for Ex audits under Details.

Intended for

Members of the Ex team performing audits, Ex representatives, and Ex component responsible.

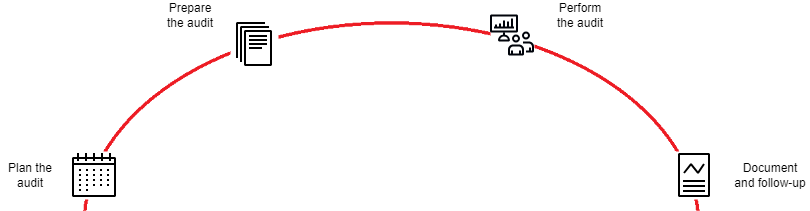

Activities

Plan the audit

The Ex internal audit shall be carried out annually for multiple organizational functions according to 7PAA015236 Ex Internal Audit schedule. This schedule is continuously updated and stored in the DMS Area for Ex Internal Audit.

Create an ADO epic in the OpEx/ExPro area to organize the audit and its findings.

Invite relevant stakeholders to the different audit sessions. Ensure sufficient time for the sessions according to the checklist (see 7PAA019424 Ex Internal Audit Template) and for follow-up questions. The audit can be carried out online or on-site, and the audit team should at least consist of two members of the Ex team.

Prepare the audit

The audit is based on the above-mentioned checklist. Adapt the sessions and the checklist to the respective functions and areas to be audited. If possible, include new focal points for recurring audit sessions. The following items should be considered for the checklist depending on the respective functions:

- Customer communication.

- User documentation.

- Certificate handling.

- Handling of Ex-relevant components.

- Project handling for Ex-certified products.

- Handling of Ex documents in development process.

- Maintenance work on Ex-certified products.

- Procurement of Ex-certified products.

- Customer order process of Ex-certified products.

- Input for track and trace of Ex-certified products.

Store the adapted audit checklist in the correct year and site folder in the DMS Area for Ex Internal Audit.

Perform the audit

Start by following up on the findings from the last audit to evaluate the organization’s ability to implement (mandatory) improvements.

Go through all questions in the checklist to address the specific requirements from ISO / IEC 80079-34 relevant to the audited organization.

Finally, in the “Room for Improvement” section, participants are encouraged to raise concerns or topics relevant for the Ex processes.

Document and follow-up

The audit shall be documented in a report (the filled-in checklist), where the findings are initially documented and relevant information from all days of the audit is summarized.

The audit report shall be stored in DMS in accordance with 7PAA014999 Minimum Retention Record. The approval workflow can then be carried out in DMS with the Ex representative as approver.

All findings shall be documented and followed up in ADO, where each finding shall be assigned a target date for closure depending on urgency and complexity.

Use the work item type “Feature” for a finding and link it to a parent epic for the audit itself. Tag the feature with “Ex Audit Finding” to help establish a query and perform further analysis on the total findings.

The PCP organization is responsible for planning and taking corrective actions to resolve any finding in an audit assigned to them. All reporting shall be done in ADO, either in the original work items or through related linked work items created by those assigned to resolve the finding.

In addition to the findings, some positive observations can also be made. These findings should give the local organization credit and be shared with other sites as examples of best practices.

Details

About internal Ex audits

The PCP organization is certified for the development and production of equipment for explosive atmospheres according to ISO / IEC 80079-34. This also requires an audit program, which shall address the effectiveness of the quality management system elements to ensure that the Ex-certified products are in conformity with the certificate.

The audit examines all aspects of the development, production, and delivery of equipment for explosive atmospheres from a certification viewpoint. This includes appropriate documentation (drawings, inspection, checklists, test records, material certificates, etc.), Ex product identification, handling, storage, training of staff, and any other elements that can affect the compliance of the Ex product to the certification parameters. The time period between two audits must not exceed 14 months.

The following parties are involved in internal Ex audits:

- Research & Development.

- Industrial Engineering.

- Supplier Quality Management.

- Procurement & Logistics.

- Planning & Fulfilment.

- Product and Portfolio Management.